Automatic Brick Making Machine For Sale

Automatic brick making machine adopts advanced production technology and control system. It makes the operation easier, save labor. Meanwhile, the production efficiency has been greatly improved. According to the degree of automation, automatic block making machine can be divided into fully automatic brick making machine and semi-automatic brick making machine. Customers can select according to their own needs. Of course, as a reliable brick making machine manufacturer with many years of production and export experience, HAMAC is commintted to providing customers with the best quality equipment and the excellent service. Therefore, if you have any questions and technologies, contact us at any time.

What Are Types of Automatic Brick Machine

The main difference between the fully automatic and semi-automatic brick making machine is the level of automation control in the brick making process.

All processes from raw material feeding to finished brick stacking, the fully automatic brick making machine is designed to operate completely independently, controlled by a programmable logic controller (PLC). The fully automatic type has higher work efficiency and output, and is more suitable for large and medium-sized projects.

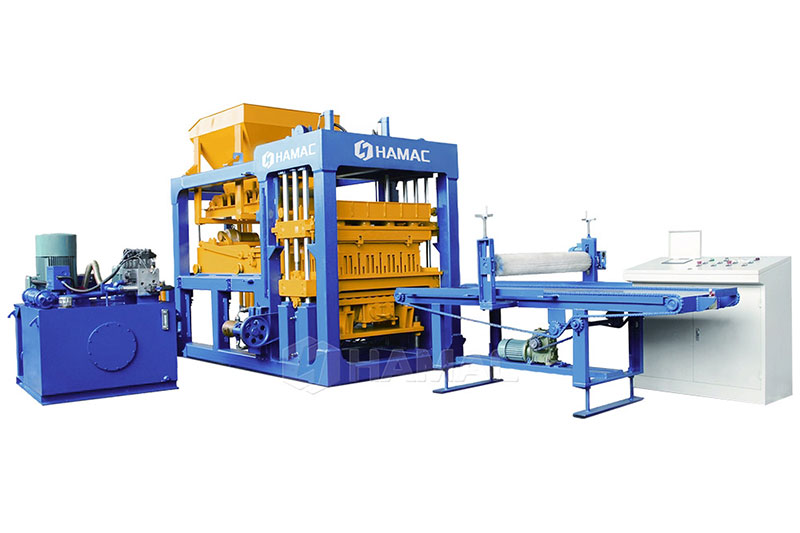

Fully Automatic Brick Making Machine

All processes from raw material feeding to finished brick stacking, the fully automatic brick making machine is designed to operate completely independently, controlled by a programmable logic controller (PLC). The fully automatic type has higher work efficiency and output, and is more suitable for large and medium-sized projects.

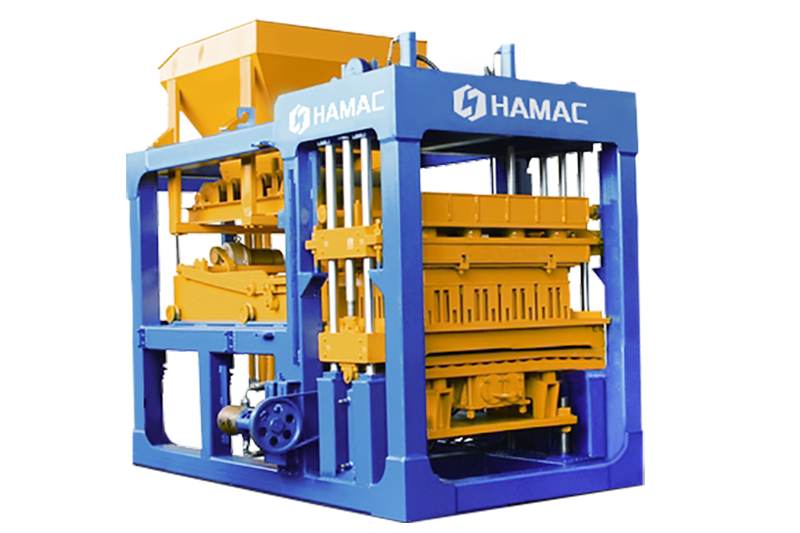

Semi-automatic Brick Making Machine

Semi-automatic brick making machines require a certain degree of manual operation during the brick making process, such as bricklaying and stacking. The machine can still produce high quality bricks with high efficiency. But compared with fully automatic type, the level of automation and efficiency are lower. However, its price is relatively low, and it is more suitable for small and medium-sized projects.

Semi-automatic brick making machines require a certain degree of manual operation during the brick making process, such as bricklaying and stacking. The machine can still produce high quality bricks with high efficiency. But compared with fully automatic type, the level of automation and efficiency are lower. However, its price is relatively low, and it is more suitable for small and medium-sized projects.

QT4-15 Automatic concrete brick Making machine Main technical parameters

| Dimension | 3600×1800×2600mm | Motor Power | 29.4KW |

| Mould Area | 550×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×550×30mm | Weight Of The Block Making Machine | 5800kgs |

Why Buy Automatic Block Machine from HAMAC

Large scale, rich production and export experience. Our company is headquartered in Zhengzhou, with production bases in Qingdao, Jinning and Xinxiang. In addition, we have special offices in the Philippines and Indonesia.

Professional and experienced technical team. Special design and R&D center, parts processing workshop, welding and assembly workshop, etc., We can fully realize the independent development, research and production of equipment.

Factory direct supply, price concessions. Large-scale production, no the third party, more affordable prices.

Professional team, sincere service. A dedicated technical team provides customers with technical guidance on installation and maintenance. Contact us for the best automatic bricking making machine price now.

FAQ - More About Automatic Block Making Machine

- The transmission system should run flexibly without abnormal sound.

- There should be no oil leakage from each part, and the total oil leakage point of the mechanical transmission part should not exceed one point.The total oil leakage points of hydraulic transmission parts shall not exceed two.

- If the transmission system adopts chain transmission, the chain and sprocket must not produce biting phenomenon. The chain tensioner should be easy to adjust, securely connected and well lubricated.

- If the transmission system adopts belt transmission, the pulleys must be aligned, the force should be uniform, and the tightness can be easily adjusted.

- The guide column is well lubricated, fit properly, and there is no jamming or shaking during operation.

- The gear reducer operates continuously for one hour under the rated working condition, and the temperature rise of the lubricating oil of the gear reducer shall not exceed 40℃.The temperature rise of the lubricating oil of the turbine reducer shall not exceed 60℃. The maximum oil temperature shall not exceed 85℃.

- The components of the hydraulic system should be arranged in an orderly manner. The pipeline direction should be clear, the connection should be firm, and it should be easy to assemble and inspect. The maximum oil temperature of hydraulic oil does not exceed 60℃.

- Research your local raw material markets. Investigate which raw material sources are plentiful, as well as transport and price.

- Research the market where your local bricksare sold. Analyze which brick is more popular, more practical, and cater to the needs of target customers.

- Find out how many brick factories are in your local area and know the strength of your competitors.

- Allocation of funds. It mainly includes equipment investment, site investment, working capital, etc.Then you can choose the suitable model of automatic block making machine based on your budget.

- High degree of automation. With the progress of society, more and more people are no longer willing to engage in simple and heavy physical activities, and the cost of labor is getting higher and higher.

- The bricks produced are of higher quality.The hydraulic automatic brick machine can realize the function of more pressurization and multiple exhaust during the pressing process, which has a great effect on improving the performance of autoclaved bricks.

- Much safer. Due to the high degree of automation, the manual work interference area is reduced, especially some brick machines are equipped with safety protection devices in the work area, which fundamentally prevents the occurrence of safety accidents.

- High working efficiency. The automatic hydraulic brick machine has good exhaust performance and can continuously produce hollow bricks for a long time.

- The control method of the built-in displacement sensor is adopted, which is not affected by environmental pollution and can accurately ensure the overall size of the brick. Equipped with a built-in pressure sensor, it can accurately measure the strength of bricks.

- It adopts high-tech, high-precision imported original parts and hydraulic parts from Siemens, Germany.

- Produce different types of bricks. With high speed, high output and complete functions, it can produce hollow bricks, solid bricks, blind hole bricks, square bricks, road paving bricks and other new building materials products of various varieties and specifications.

- Low noise, low power consumption, energy saving and power saving.

- To maximize the quality of the bricks produced.After setting the size and strength of the bricks, any brick that do not meet the requirements can be automatically returned to the raw material warehouse, and then pressed after mixing to ensure the quality to the greatest extent.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.