What Is Concrete Trailer Pump

Trailer concrete pump can’t move by itself. Therefore, it is also called stationary concrete pump or static concrete pump. There are two types of concrete trailer pump for sale in HAMAC, one is driven by a diesel engine and the other is driven by an electric motor. Since trailer concrete pump is equipped with wheels, Just install the pump on a simple trailer can it be easily moved on the construction site. It can also be pulled and towed on the road. Concrete trailer pump is a commonly used concrete conveying equipment for construction projects.

What Are Excellent Performances of Concrete Trailer Pump For Sale In HAMAC

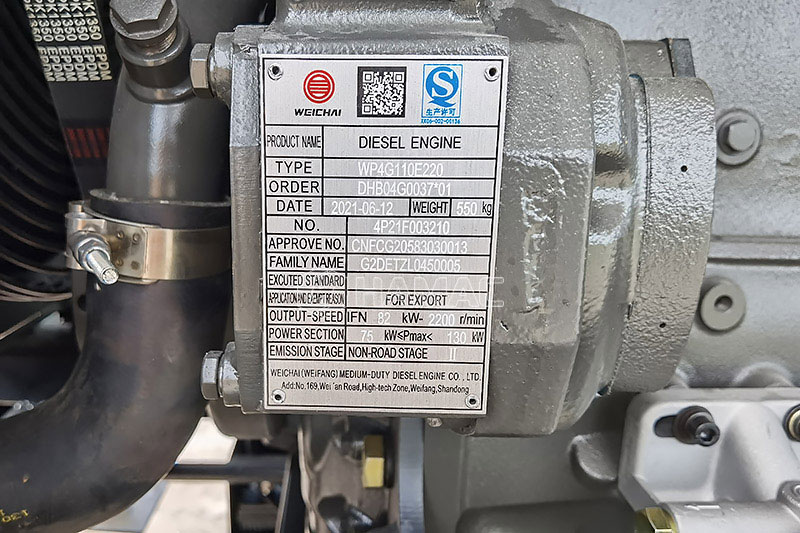

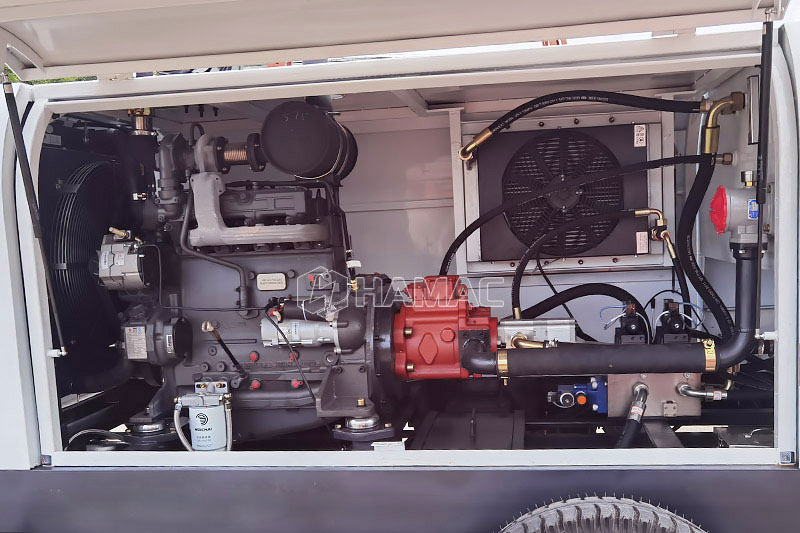

Power supply system. The diesel engine power system adopts Yuchai, Weichai Deutz or Cummins diesel engines. The electric motor adopts well-known domestic and foreign brand motors, such as, WANNAN, MENGNIU, and Siemens Beide Motor, etc.

Radiator. The use of air-cooled plate-fin radiators ensures that the diesel concrete pump system operates at the highest allowable temperature.

Hydraulic oil pump. The main oil pump is from Kawasaki. And valves are from Huade or OM from Italian.

Lubrication system. The centralized lubrication system adopts a progressive distributor to supply oil to each lubrication point in turn, and the lubrication time can be set at regular intervals. It has the advantages of accurate oil injection and oil saving.

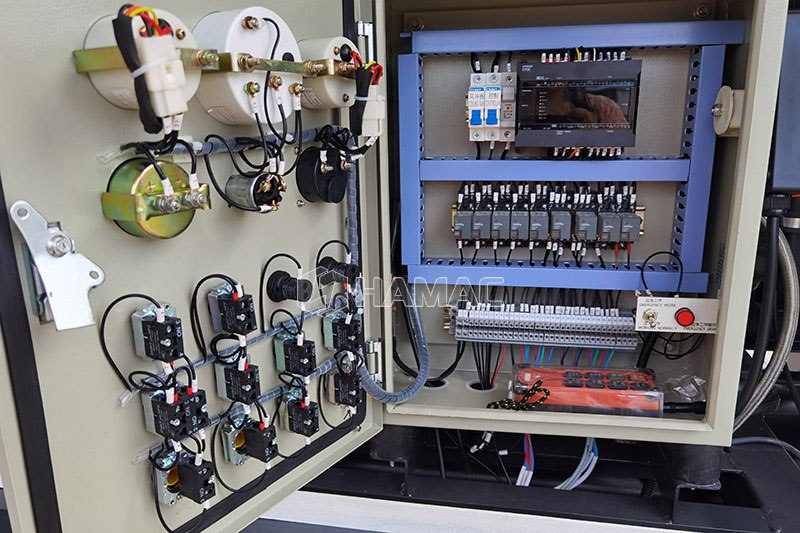

Electric parts. The main electrical components are from Schneider, Omron or Siemens. The reliability of the electronic control system is greatly improved.

Pipe valve.Valves are cast with manganese steel, and the wear-resistant surface is processed with wear-resistant materials, which has the characteristics of high pressure resistance and wear resistance.

Glasses plate cutting ring. Glasses plates and cutting rings are made of wear-resistance alloy for longer service life.

Hydraulic rubber hose joints. Equipped with world famous brand parts to ensure the safety of the hydraulic system, which can ensure no leakage.

Models of Concrete Trailer Pump For Sale for Sale in HAMAC

Electromotor trailer concrete pumps:

| Item | Unit | S Valve Concrete Pump | |||||||

|---|---|---|---|---|---|---|---|---|---|

| HBT30 | HBT40 | HBT50 | HBT60 | HBT80 | |||||

| Theoretic Concrete Delivery Volume | Low Pressure | M3/H | 30 | 40 | 50 | 60 | 80 | ||

| High Pressure | M3/H | / | / | 23 | 36 | 48 | |||

| Concrete Delivery Pressure | Low Pressure | MPa | / | / | 5.8 | 6.3 | 8.3 | ||

| High Pressure | MPa | 10 | 10 | 12 | 13 | 16 | |||

| Hydraulic Pressure | MPa | 25 | 28 | 28 | 28 | 28 | |||

| Electric Motor Speed | R/Min | 1480 | |||||||

| Main Hydraulic Pump | JINDA | Kawasaki | |||||||

| Main Cylinder Dia./Pole Dia. x Stroke | Mm | Φ 80/55 x 845 | Φ 100/70 x 1100 | Φ 110/70 x 1300 | Φ 120/80 x 1650 | Φ 140/90 x 1800 | |||

| Diameter Of Delivery Cylinder | Mm | 140 | 160/180 | 180 | 200 | 200 | |||

| Electric Motor Power | KW | 37 | 45 | 55 | 90 | 110 | |||

| Capacity Of Hydraulic Oil Tank | L | 200 | 370 | 370 | 560 | 560 | |||

| Hopper Capacity | M3 | 0.4 | 0.55 | 0.6 | |||||

| Overall Weight | Kg | 2300 | 3500 | 3600 | 5000 | 5600 | |||

| Max. Delivery Distance | Vertical | M | 100 | 160 | 160 | 160 | 160 | ||

| Horizontal | M | 300 | 500 | 500 | 800 | 1000 | |||

Diesel engine trailer concrete pumps

| Item | Unit | DHBT30 | DHBT40 | DHBT50 | DHBT60 | DHBT80 | DHBT90 |

|---|---|---|---|---|---|---|---|

| Theoretical Capacity | M³/H | 30 | 40 | 50 | 60 | 80 | 90 |

| Delivery Pressure | Mpa | 10 | 10 | 10 | 13 | 16 | 22 |

| Max. Pump Times | Times/Min | 24 | 20 | 22 | 22 | 23 | 23 |

| Delivery Height | M | 120 | 120 | 120 | 180 | 180 | 350 |

| Delivery Distance | M | 500 | 500 | 500 | 600 | 1000 | 1500 |

| Distribution Valve Type | S Tube Valve | S Tube Valve | S Tube Valve | S Tube Valve | S Tube Valve | S Tube Valve | |

| Delivery Cylinder Type | Mm | Φ140×1200 | Φ180×1300 | Φ180×1300 | Φ200×1650 | Φ200×1650 | Φ200×1800 |

| Main Oil Pump | Mm | Φ80/55×1200 | Φ100/70×1300 | Φ110/70×1300 | Φ125/80×1650 | Φ125/Φ80×1650 | Φ125/Φ80×1650 |

| Oil Tank Capacity | L | 260 | 370 | 370 | 560 | 560 | 560 |

| Hopper Capacity | L | 400 | 400 | 400 | 800 | 800 | 800 |

| Filling Height | Mm | 1100 | 1100 | 1100 | 1400 | 1400 | 1400 |

| Outlet Diameter | Mm | Φ125 | Φ150 | Φ150 | Φ180 | Φ180 | Φ200 |

| Delivery Pipe Inner Diameter | Mm | Φ125/Φ100 | Φ125 | Φ125 | Φ125 | Φ125 | Φ125 |

| Engine Power | Kw | 56 | 82 | 82 | 129 | 129/145 | 199 |

| Rated Spped | R/Min | 2200 | 2200 | 2300 | 2300 | 2300 | 2300 |

| Idling Speed | R/Min | 800 | 800 | 800 | 800 | 800 | 800 |

| Voltage | V | 24V | 24V | 24V | 24V | 24V | 24V |

| Fuel Tank | L | 150 | 150 | 150 | 150 | 150 | 150 |

| Hydraulic Oil-Way Type | Open | Open | Open | Open | Open | Open | |

| Max. Oil Pressure | MPa | 26 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 |

| Max. Oil Pressure For Mixing System | MPa | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Max. Mixing Speed | R/Min | 24 | 24 | 24 | 24 | 24 | 24 |

| Slump | Mm | 80~200 | 80~200 | 80~200 | 80~200 | 80~200 | 80~200 |

| Maximum Aggregate Size | Mm | ≤30(≤20) | Aggregate 40 | Pebble 50, Aggregate 40 | Pebble 50, Aggregate 40 | Pebble 50, Aggregate 40 | Pebble 50, Aggregate 40 |

| Overall Dimension | Mm | 4970×1680 ×2580 | 5270×1860 ×2580 | 6600×1930 ×2190 | 6600×1930 ×2190 | 6600×1930 ×2190 | 6800×2100 ×2350 |

| Wight | Kg | 3500 | 4500 | 4500 | 6500 | 6800 | 7000 |

| Towing Speed | Km/H | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

Working Principle of Trailer Concrete Pump

The piston of the concrete cylinder is respectively connected with the piston rod of the main oil cylinder. Under the action of hydraulic oil, the main oil cylinder reciprocates, one cylinder advances, and the other cylinder retreats. The outlet of the concrete cylinder is connected to the hopper, one end of the distribution valve is connected to the outlet, and the other end is connected to the swing arm through a spline shaft, and can swing left and right under the action of the swing cylinder.

When pumping concrete, under the action of the main cylinder, one piston advances and the other piston retreats. At the same time, under the action of the swing cylinder, the distribution valve communicates with one concrete cylinder, and the other concrete cylinder communicates with the hopper. Thus, the retreating piston sucks the concrete material in the hopper into the concrete cylinder, and the other piston continues to move forward to send the concrete material in the concrete cylinder to the distribution valve to pump out.

When the concrete piston retreats to the end of the stroke, the reversing device in the water tank is triggered to make the two main cylinders reversing. At the same time, the direction of the two swing oil cylinders is reversed, so that the distribution valve communicates with the concrete cylinder, and the other concrete cylinder communicates with the hopper. At this time, one piston retreats and the other piston advances. In this way, continuous pumping is achieved.

Content Index

- What Is Concrete Trailer Pump

- What Are Excellent Performances of Concrete Trailer Pump For Sale In HAMAC

- Models of Concrete Trailer Pump For Sale for Sale in HAMAC

- Working Principle of Trailer Concrete Pump

- Choose Diesel Concrete Trailer Pump or Electric Concrete Trailer Pump

- What Are Components of A Trailer Mounted Concrete Pump

- Buy Concrete Trailer Pump For Sale with Various Specifications in HAMAC

Choose Diesel Concrete Trailer Pump or Electric Concrete Trailer Pump

Electric trailer concrete pump relies on an external three-phase 380V voltage. The motor rotates to provide power to the main oil pump, thereby driving the operation of the entire hydraulic system.

Diesel trailer concrete pump relies on its own diesel engine to provide power to the main oil pump and drive the operation of the entire system.

Consumption costs for electric powered pumps are much lower than for diesel powered pumps. However, the construction site should have a three-phase power supply. If not, a transformer needs to be prepared, and the cost will be high.

The diesel trailer concrete pump is more convenient to use, as long as there is diesel, it can work anywhere.

The electric trailer-mounted concrete pump has low noise and little environmental pollution. Diesel trailer-mounted concrete pumps are noisy and pollute the environment.

For trailer-mounted concrete pumps of the same model, diesel-powered ones are more expensive than electric ones.

The diesel type require frequent maintenance of diesel engines, and later maintenance costs are higher than the electric type.

What Are Components of A Trailer Mounted Concrete Pump

It is mainly composed of power device, concrete pumping mechanism, concrete distribution valve, concrete mixing mechanism, hydraulic system, electric control system, lubrication system and supporting walking device.

Power device

The concrete trailer pump power unit has two kinds of engines, diesel engine and electric motor. The selection of motor power and main oil pump must match. The main oil pump adopts axial plunger type variable pump. The output flow is directly proportional to the driving speed and the displacement of the pump, and can be discharged steplessly between maximum and zero. It has the functions of constant power control, pressure cut-off and electric proportional flow regulation.

Pumping mechanism

The pumping system is a power actuator that converts hydraulic energy into mechanical energy. Its function is to push the concrete to overcome the pipeline resistance and reach the pouring site. It is mainly composed of two main cylinders, a water tank, a reversing mechanism, two concrete cylinders, two concrete cylinder pistons, a swing arm, two swing cylinders, a distribution valve, a discharge port and a hopper.

Pumping mechanism

The pumping system is a power actuator that converts hydraulic energy into mechanical energy. Its function is to push the concrete to overcome the pipeline resistance and reach the pouring site. It is mainly composed of two main cylinders, a water tank, a reversing mechanism, two concrete cylinders, two concrete cylinder pistons, a swing arm, two swing cylinders, a distribution valve, a discharge port and a hopper.

Hopper and mixing system

The volume of the hopper should be adapted to the concrete delivery volume of the pump. The upper part of the hopper is equipped with a grid screen to prevent large aggregates or sundries from entering the hopper. There are stirring blades in the hopper, which can carry out secondary mixing on the concrete mixture, and has the feeding function of pushing the concrete mixture to the concrete distribution valve.

Support and walking mechanism

It is mainly composed of underframe, axle, including road wheels, guide wheels and outriggers. The bottom frame is the basic part for the connection of various parts of the trailer pump, which is welded by profile and steel plate, and plays a supporting role for each part. The front of the bottom frame is connected with the hopper, and there is a trailer at the rear, which can transport the towed concrete pump from one construction site to another easily.

Water pump device

The water pump device is a kind of water washing device used by the gate valve to tow the pump to clean the pipeline and the pump. It is composed of water tank, water filter, water pressure gauge, oil tank, water valve four-way block, spit valve, suction valve, etc.

Cooling system

There are three cooling methods for hydraulic oil, water cooling, air cooling, water and air cooling. Different cooling methods can be selected according to regional climate differences and construction conditions.

Buy Concrete Trailer Pump For Sale with Various Specifications in HAMAC

The pumping horizontal distance and vertical height of the concrete trailer pump are related to the concrete grade and the outlet pressure of the trailer concrete pump. As a leading concrete trailer pump manufacturer in China, HAMAC can supply various models of trailer concrete pump for sale with different pumping heights and horizontal distances.

Feel free to inquiry us for technical guidance and the best concrete pump trailer price.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.