Brick Making Machine For Sale

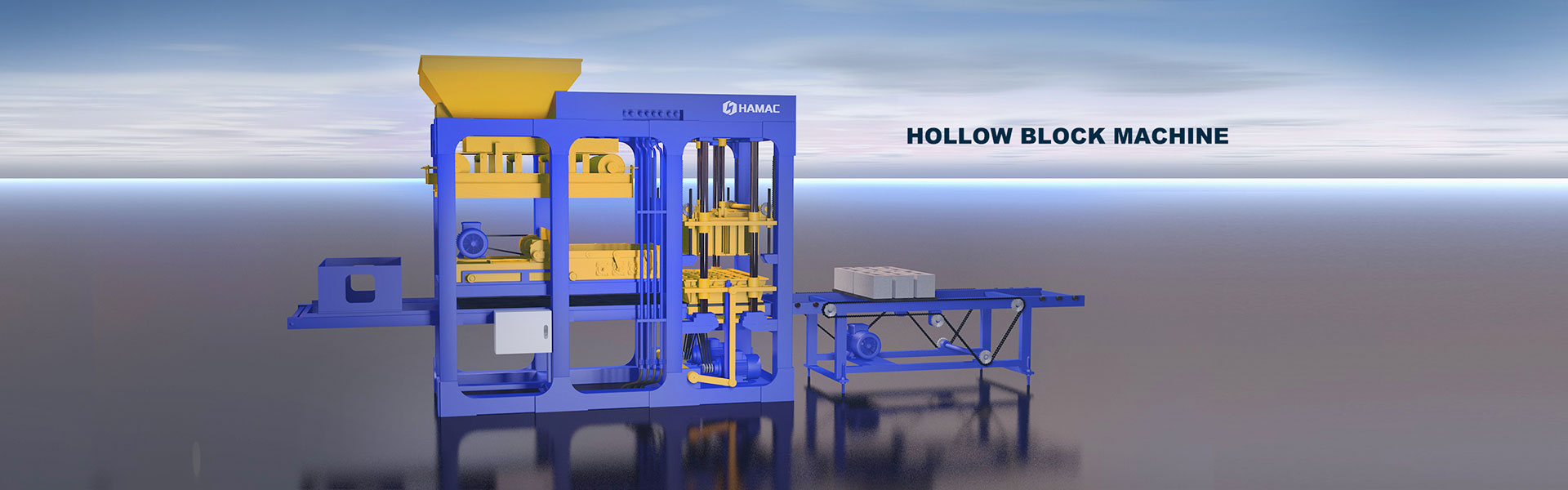

Brick making machine is one of the most important machines in the construction industry because all hollow blocks, solid blocks, paving stones and curbs used in the construction sector are all produced by these block making machines. Our company can provide customers with various models of cement brick making machine, hollow block machine. Have any need? Contact us for technical support at any time.

Hollow block machine is a popular kind of brick making machine designed to produce concrete hollow blocks. Meanwhile, it can also produce solid blocks and paver blocks. HAMAC can supply manual type, semi-automatic, fully automatic type hollow block machine. Check more now.

FAQ - More About Brick Making Machine For Sale

Brick making machine can be divided into vacuum brick machine and burn-free brick machine. The former is an adobe made of soil, which requires a lot of soil to make, wasting resources and polluting the environment. The latter is to use waste coal gangue, shale rock, stone powder, fly ash, slag, slag, gravel, sand, cement and other raw materials, after scientific proportioning, adding water and stirring, to make different types of cement bricks, hollow bricks, etc. Moreover, without the firing process, bricks can leave the factory after a short period of drying, which is more environmentally friendly and resource-saving.

From whether the brick making machine can be moved, it can be divided into fixed brick making machine and mobile brick making machine.

From the degree of automation, it can be divided into manual, semi-automatic and fully automatic brick making machine.

According to different forming principles, it can be divided into pneumatic block machine, vibration brick machine and hydraulic brick making machine.

According to the output size, it can be divided into small, medium and large brick making machine.

Mobile Brick Making Machine

The equipment is a fully autonomous unit that can be easily and inexpensively transported almost anywhere on a trailer. However, most of the process is done manually, such as the preparation of the mortar, transfer of the mortar to the machine, etc. Therefore, you need more workers than other machines. It is suitable for projects with a small amount of work and a small budget.

Semi-automatic Brick Making Machine

From raw material mixing, raw material conveying, and brick making, all are done automatically by machinery, while semi-automatic brick making machine requires you to manually control the operation buttons or levers. One person is required to operate the control system all the time to complete the production of bricks continuously. It has high production efficiency, simple operation, convenient maintenance, and the price is cheaper than fully automatic. But the output is not as high as fully automatic, and more labor is required. The semi-automatic brick making machine is suitable for small projects that require high production line capacity, but the budget is not so high.

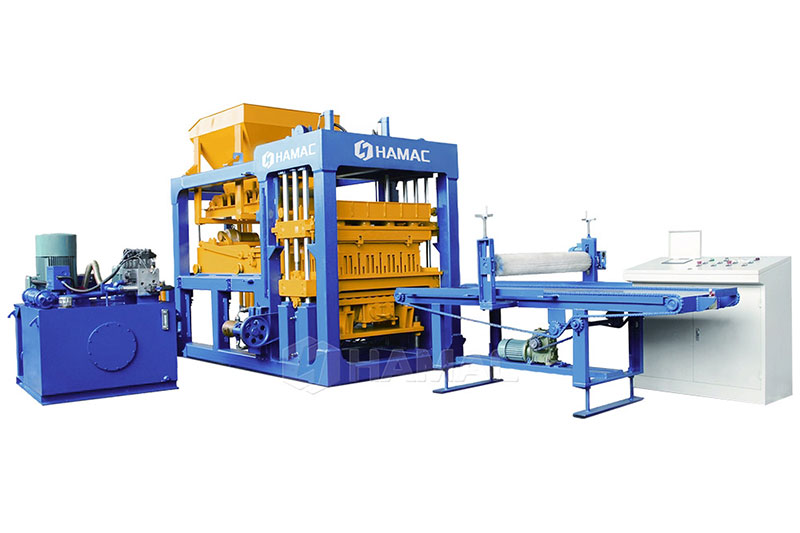

Fully-automatic Brick Making Machine

From the mixing of raw materials, the conveying of raw materials, to the shaping of bricks, it is all fully automated. The PLC control system is equipped with a preset program, which can automatically produce bricks. The fully automatic brick making machine can greatly save manpower and has high production efficiency. But the relative disadvantage is that due to the rich configuration of the automatic brick making machine, the cost is relatively high. It is suitable for projects with high requirements on brick output and high budget.

Manual Brick Making Machine

Manual block machine requires humans to add raw materials to the mold, and then the machine mold vibrates to form the bricks. The advantage is that the operation is simpler, the price is cheaper, and the maintenance is very convenient. However, the physical exertion is large, the output is low, and the efficiency is low.

- The layout is compact and reasonable. Small footprint, compact layout and small production workshops.

- High adaptability and good scalability. The back end can be equipped with high or low brick receiving line, and can also be expanded into a production line with a higher degree of automation.

- The system is simple and the performance is stable and reliable.

- High flexibility. Modular design and layout, the required products can be customized according to the needs to meet the individual needs of customers.

- High economic applicability. Small investment, big return.

You can choose the appropriate type and model from the five aspects, raw material for brick making, type of brick produced, production scale, investment capacity, whether the type of brick machine matches and cost performance. First, your budget and planned output are the most important factors to consider. Then you can decide to purchase a fully-automatic or semi-automatic block making machine.

Choose a reliable and professional manufacturer. Don’t just look at the price when purchasing a brick machine. High-quality product quality and perfect after-sales service are the powerful guarantee for project production.

Check if the brick machine manufacturer has a complete processing system to ensure the quality of the equipment and the service process.

The advanced level of processing equipment of brick machine manufacturers. Advanced processing equipment directly reflects the quality of the brick machine and is a strong support for the production and operation of brick enterprises.

Whether the parts of the brick machine manufacturer are strictly handled. Whether raw materials and accessories are selected from reliable brands. This will directly affect the quality and service life of the brick machine.

Choose manufacturer with good after-sales service. A good level of after-sales service means that customers will not be troubled by unnecessary problems and troubles after purchasing the brick making machine. The manufacturer can carefully solve the installation problems of machinery and equipment for customers and provide detailed operation training.

Our company can provide different brick making machines for different budgets and projects. We can recommend the most suitable brick making machine for you according to your requirements, your countries and regions. Our engineers will also provide you with technical information and details of the local market to help you choose the most suitable machine for your business. Feel free to inquiry us for the best quotation of brick making machine for sale in HAMAC now.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.