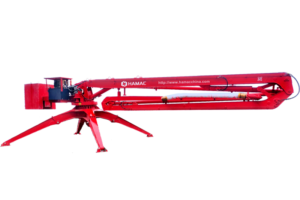

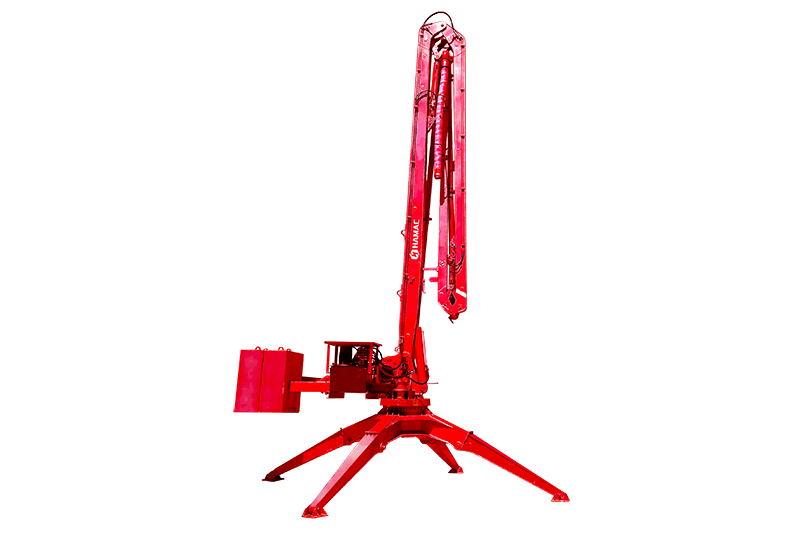

Spider Concrete Placing Boom

Spider concrete placing boom is the terminal equipment for pumping concrete. It is an equipment for expanding the scope of concrete pouring and improving the mechanization level of pumping construction.

- 13-21m length boom as options

- Famous brand hydraulic parts

- Mobile type and stationary type

What Is Spider Concrete Pump

Spider concrete pump, with another name of spider concrete placing boom, is a kind of mobile concrete placing boom. It got its name because the machine is equipped with a walking mechanism that looked like spider legs. Its function is to send the pumped concrete through the pipeline to the formwork of the component to be poured. The combined motion of the two-part turret can cover all cloth points within the cloth radius. As the supporting equipment of concrete pump, spider concrete placing boom can increase the concrete pumping range by connecting with the concrete pump. Meanwhile, it can effectively solve the problem of material distribution in wall pouring, which play an important role in improving construction efficiency and reducing labor intensity.

Why Buy Spider Concrete Placing Boom for Sale in HAMAC

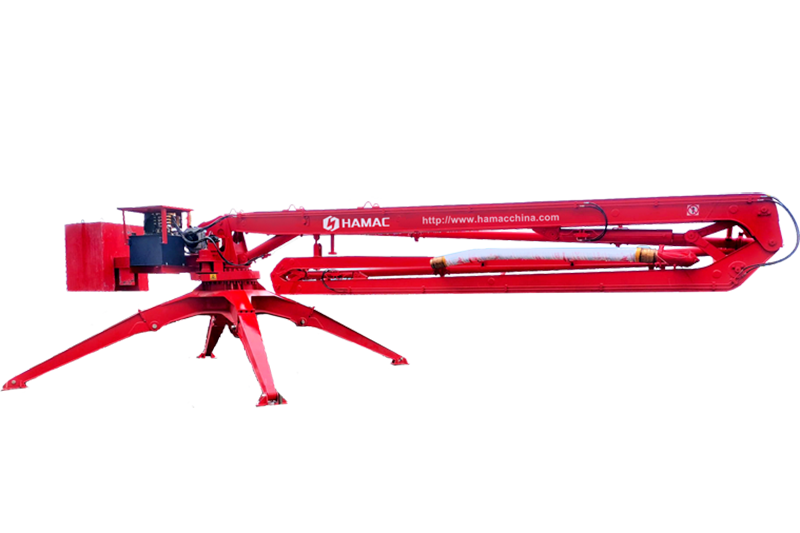

- Three-section boom, fully hydraulic drive.The boom is easy to retract and can be rotated 360 degrees, with a wide range of operations.

- Equipped with remote control, whichcan better control the concrete pouring arm.

- Dual system control. If there is a problem in one of the two systems, the other control system can start working immediately.

- Stable outrigger support, equipped with self-balancing device.There is no need to use bolts to connect the concrete placing machine to the ground.

- The whole machine is made of high-quality steel plate with optimized design.Lighter in weight, more suitable for ground load bearing, convenient for tower crane hoisting.

- The main electrical components are imported from the United States and Europe, with high quality, stable performance and low failure rate.

- The whole machine can be hoisted separately for quick assembly.

Models of Spider Concrete Pump for Sale in HAMAC

| Item | HGY13 | HGY15 | HGY17 | HGY21 |

|---|---|---|---|---|

| Max. Placing Radius (M) | 13 | 15 | 17 | 21 |

| Big Arm Length (M) | 3.7 | 6 | 6.66 | 6.496 |

| Big Arm Elevation (°) | -2~84.4 | 0~70 | 0~65 | 0~65 |

| Medium Arm Length (M) | 4.52 | 5 | 5.73 | 4.585 |

| 4.59 | ||||

| Medium Arm Elevation (°) | 0~180 | 0~180 | 0~180 | 0~180 |

| 0~180 | ||||

| Small Arm Length (M) | 4.78 | 4 | 4.61 | 5.029 |

| Small Arm Elevation (°) | 0~180 | 0~180 | 0~180 | 0~180 |

| Hose Length (M) | 3 | 3 | 3 | 3 |

| Concrete Delivery Pipe (Mm) | Ø125×6 | Ø125×6 | Ø125×6 | Ø125×6 |

| Tail Rotary Radius (M) | 2.72 | 2.81 | 3.51 | 3.51 |

| Total Power (Kw) | 4 | 4 | 5.5/7.5 | 11 |

| System Pressure (MPa) | 24 | 24 | 24 | 24 |

| Rotary Speed (R/Min) | 0.3—0.8 | 0.3—0.8 | 0.3—0.8 | 0.3—0.8 |

| Rotary Range (°) | 0~360 | 0~360 | 0~360 | 0~360 |

| Supporting Legs Span (M) | 3.15×3.15 | 4×4 | 4.6×4.6 | 4.6×4.6 |

| Overall Height (M) | 2.9 | 2.6 | 3.2 | 3.2 |

| Bare Machine Weight (Kg) | 2700 | 3230 | 5000 | 10000 |

| Balance Weight (Kg) | 2×900 | 2×1100 | 2200 | 2×2500 |

| Control Mode | Panel/ Wireless Remote Control | Panel/ Wireless Remote Control | Panel/ Wireless Remote Control | Panel/ Wireless Remote Control |

How Does Spider Concrete Placing Boom Work?

As the terminal equipment for pumping concrete, the function of the concrete placing boom is to send the pumped concrete through the pipeline to the formwork of the component to be poured. There is a pipeline inlet under the concrete placing boom, just connect the end of the pipeline of the concrete pump to the front end of the feeding elbow of the concrete placing boom to complete pumping construction of the pipeline. The concrete in the hopper, under the pumping working pressure of the concrete pumping mechanism, continuously transports the concrete to the distribution range of the construction site through the rotation of the concrete delivery pipeline, the main beam frame and the second section pipe.

Content Index

- What Is Spider Concrete Pump

- Why Buy Spider Concrete Placing Boom for Sale in HAMAC

- Models of Spider Concrete Pump for Sale in HAMAC

- How Does Spider Concrete Placing Boom Work?

- What Are The Components of Spider Concrete Pump?

- What Are Advantages of Hydraulic Spider Concrete Pump

- How To Choose Suitable Model of Spider Concrete Placing Boom

What Are The Components of Spider Concrete Pump?

Main frame. It is composed of supporting angle steel, pipe bracket, tie rod, main beam. The main beam frame is installed on the slewing support frame, and can do 360° full rotation through the slewing support. There is a pipe bracket on the upper part of the main beam at the front end to fix and support the conveying pipeline of the concrete placing machine. And a balance frame is installed at the rear end to achieve counterweight balance.

Balancing frame. It consists of a balance frame and a counterweight box. It is installed at the rear flange of the main beam and fixed with screws to ensure its working stability.

Block support contractors. It is welded by angle steel and steel plate. The slewing bearing is installed at the lower part of the main beam frame to support the weight of the whole machine. The upper main beam frame can realize 360° rotation through the ball type slewing bearing of the support seat, so as to realize different ranges of concrete placing. The telescopic legs can be adjusted for horizontal distance to achieve their working stability, and each leg must be leveled during work.

Delivery pipeline. It is composed of fixed standpipe, straight pipe, 90° elbow, movable elbow, manual pipe, pipe clamp. The conveying pipeline is fixed on the main beam frame, the 90° elbow at the rear end is connected to the end of the concrete pump conveying pipeline. And the manual pipe at the other end can be used to place concrete within 360° through the movable elbow.

What Are Advantages of Hydraulic Spider Concrete Pump

The hydraulic spider concrete pump is more flexible. The booms are currently “R-type folding boom” and “2-type joint boom”, which can be freely stretched and rotated to step over obstacles. When the floor or column is built shallowly, the protruding steel structure will not affect the rotation of the jib.

More convenient to use. It is a kind of concrete pouring equipment operated by intelligent remote control. When the floor is poured, the steel bars connected on the floor are bound with iron wires. If the workers walk on the ground during construction, these iron wires will be deformed and dislodged when they are stepped on. The use of wireless remote control avoids the construction personnel from walking and improves the construction efficiency.

Improve the construction efficiency. The hydraulic placing machine can be poured and formed at one time, and it can be rotated 360 degrees hydraulically, which can fully achieve the effect of intelligent concrete pouring.

Much safer. There are three ways to install the hydraulic distribution machine, the fixed installation of the formwork, the installation in the elevator shaft, and the installation of the floor opening. No matter which installation method is used, the construction can only be carried out when the safety factor is reached. There is no need to worry about potential safety hazards caused by vibration generated by concrete pouring.

The spider hydraulic concrete placing boom can be easily moved by a tower crane close to the building. Meanwhile, wheels can also be added for traction by people or forklifts.

How To Choose Suitable Model of Spider Concrete Placing Boom

First, consider the length and width of the building or floor. Because this determines the working radius of the mobile concrete placing boom required. Then choose the appropriate length of the boom.

Second, whether the spider placing boom is lifted by a tower crane or other lifting equipment. Then, you also need to consider how much weight the crane can lift.

Third, whether there is a three-phase power supply at the construction site. The spider concrete placing boom for sale is powered by electricity.

There are spider concrete pump for sale in HAMAC with 13m, 15m, 17m and 21m arm support for customers to choose. Contact us now for more technical guidance and model recommendations.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECH Industrial Development Zone, Zhengzhou,China.