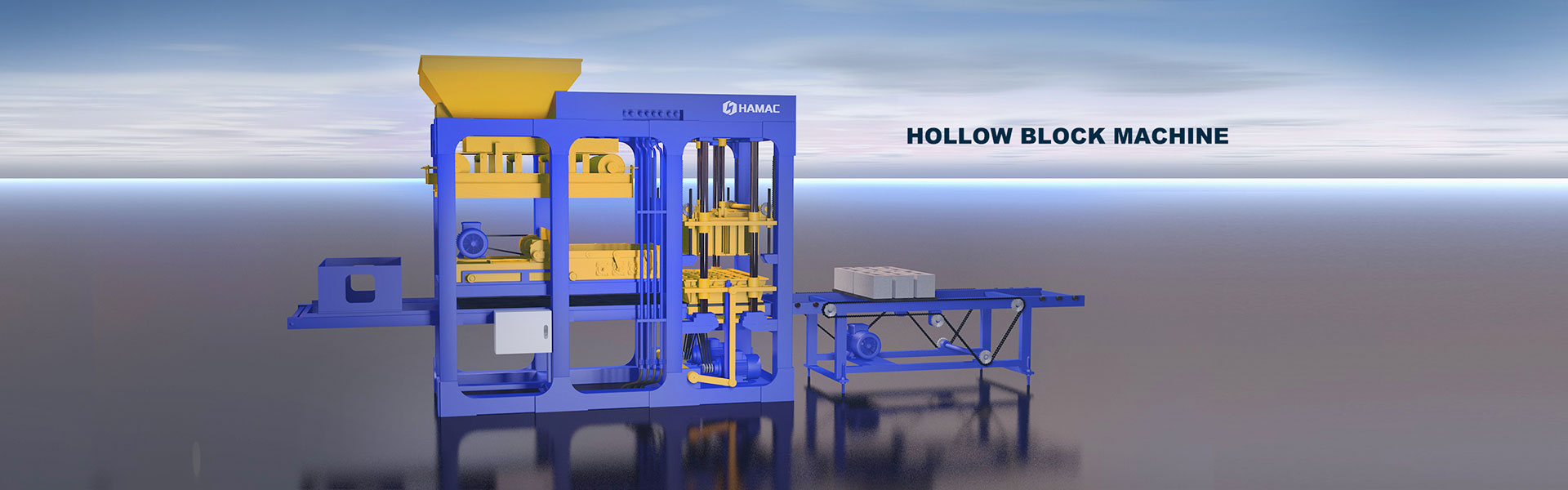

About Concrete Block Machine Manufacturer - HAMAC

A trusted concrete block machine manufacturer. Since its establishment in 2005, our company has always adhered to the corporate tenet of “Technology Achieves Quality”, and has provided customers with dedicated and wholehearted services. Concrete block machine for sale in our company has been exported to many countries and regions in the world, and has received wide acclaim from customers.

Equipment quality assurance. The equipment produced by our company has technical advantages such as energy saving, environmental protection, easy use, and high degree of automation. At the same time, the best quality parts are selected to reduce the failure rate of equipment and reduce maintenance costs.

Continuous technological innovation. HAMAC has a research and development center, a parts processing workshop, a welding assembly workshop, and a mold heat treatment workshop, which integrates independent development, research, production and sales of equipment.

Excellent after-sales service. Dedicated after-sales maintenance service team. If you encounter any problems, please feel free to contact us for technical support, we are online 24 hours a day to provide you with service.

QT4-15 Automatic concrete block machine Main technical parameters:

| Dimension | 3600×1800×2600mm | Motor Power | 29.4KW |

| Mould Area | 550×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×550×30mm | Weight Of The Block Making Machine | 5800kgs |

QT5-20 Automatic concrete brick making machine Main technical parameters:

| Dimension | 3650×2100×2720mm | Motor Power | 20KW |

| Mould Area | 550×1100mm | Vibration Force | 50KN |

| Working Cycle | 16-25S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 1100×550×30mm | Weight Of The Block Making Machine | 6000kgs |

QT6-15 Automatic cement block machine Main technical parameters:

| Dimension | 4410×2000×2510mm | Motor Power | 36.4KW |

| Mould Area | 680×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×680×30mm | Weight Of The Block Making Machine | 6000kgs |

QT8-15 Automatic concrete block machine Main technical parameters:

| Dimension | 4900x2120x2650mm | Motor Power | 46.4KW |

| Mould Area | 850×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 900×850×35mm | Weight Of The Block Making Machine | 6500kgs |

What Services Can We Provide

Provide a full set of conventional technical formula and process flow.

According to the needs of users, the production scale, production demand, and determine the appropriate model.

On-site installation and commissioning, training of technical and equipment operation and maintenance personnel.

Assist customers in system upgrades and improve equipment production efficiency.

Continuously carry out technical updates to provide customers with new molds and various accessories.

Regular return visits and two-way communication with customers.

Assist customers to establish production and quality management systems to ensure all-round development.

Professional after-sales service team to provide you with perfect after-sales technical support.

What to pay attention to when choosing a good concrete block machine manufacturer

Brick machine configuration

The transmission system should run flexibly without abnormal sound.

Perform a power-on test. All parts should not leak oil.

The transmission system adopts chain transmission, the chain and the sprocket must not produce biting phenomenon, the chain tensioning device should be easy to adjust, the connection should be firm, and there should be good lubrication.

The transmission system with belt transmission is adopted, the pulleys must be aligned, the force should be uniform, and the tightness can be easily adjusted.

The guide column is well lubricated, fit properly, and there is no jamming or shaking during operation.

When the reducer runs continuously for one hour under the rated working conditions, the temperature rise of the lubricating oil of the gear reducer shall not exceed 40°C, and the temperature rise of the lubricating oil of the turbo reducer shall not exceed 60°C.

The components of the hydraulic system should be arranged in an orderly manner, the pipeline direction is clear, the pipe layout is neat, the connection is firm, easy to assemble and inspect, and the maximum oil temperature of the hydraulic oil does not exceed 60°C.

Brick machine appearance

The paint should be uniform, smooth and shiny. There must be no wrinkled skin, peeling, paint leakage, flow marks, air bubbles, etc. on the surface.

There should be no hammer marks or surface protrusions on the casing. The edges should be rounded and smooth, and the installation position should be correct, firm and reliable.

The exposed parts of the parts should be treated with anti-rust, the surface of the casting should be smooth and smooth, and there should be no flashes and burrs such as blisters and pores.

The welding seam should be beautiful, and there must be no missing welding, cracks, arc craters, slag inclusions, burn through, meat bites and other phenomena and defects. The width of the same weld should be consistent, and the difference between the maximum width and the minimum width should not exceed.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.