Concrete Mixer with Pump

Concrete Mixer with pump can realize on-site mixing and continuous pumping, which can greatly improve the construction efficiency. Concrete mixer with pump for sale in HAMAC can pump 70m high, 300m horizontal distance with diesel engine and electric motor for customers to choose.

What Is Concrete Mixer with Pump

It is a kind of small concrete pump that adopts a fully automated construction operation system and integrates feeding, mixing and high-pressure pumping. The machine is usually in the form of trailer type for easy movement. Therefore, it is widely used in road construction, building construction, tunnel construction, bridge construction, slope protection construction, etc. Our company can provide customers with trailer and twin shaft type, choose the suitable model based on your requirements now.

Why Choose Trailer Concrete Mixer With Pump

The equipped concrete mixer will mix all the ingredients needed to produce high-quality concrete. And then the pump can ensure that the concrete is pumped directly and continuously to where it is needed when the concrete is in the best condition.

- Integrated design, small footprint, flexible movement and convenient construction.

- Greatly improve the construction efficiency. Only one machine is needed to realize mixing and continuous pumping, which can make the construction efficiency reach 4-6 times than that of the traditional concrete mixer and pump.

- Save construction cost.Concrete mixing and pumping are combined into one, only one machine can achieve two functions, which can reduce the purchase cost.

- Reduce labor force, and save labor cost. In the process of mixing and pumping, only one operator is required to complete the two procedures, which greatly saves labor.

- Fully automatic operation, equipped with intelligent and intuitive electronic system, simple operation and stable performance.

- Trailer-type design, can be easily transported by forklift or trailer, convenient to move, thus greatly shortening construction period.

Models of Concrete Mixer with Pump for Sale in HAMAC

| Parts Name/Parameters | Parts Specification | ||||

|---|---|---|---|---|---|

| Models | HBT15 | DHBT15E | DHBT15 | DHBT15 PRO | |

| Power | Power supply model | Electric Motor | Diesel engine | Diesel engine | Diesel engine |

| Electric Component | Siemens/Schneider/Omron | ||||

| Mixing System | Mixer | JZM450 drum mixer, 750L charging hopper, 450L concrete output per batch | |||

| Mixing Motor | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

| Hoist Motor | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

| Submersible Pump | 0.75kW | 0.75kW | 0.75kW | ||

| Max. Theoretical Mixing Output | 18-22m³/h | ||||

| Pumping System | Main Motor | 45kW, electric motor | 52kW, Weichai diesel engine | 62kW, Weichai diesel engine | 92kW, Weichai diesel engine |

| Motor Rated Speed | 1480 RPM | 1800 RPM | 1800 RPM | 1800 RPM | |

| Mian Hydraulic Oil Pump | KAWASAKI K3V112 | Domestic brand K3V80 | KAWASAKI K3V112 | KAWASAKI K3V140 | |

| Double Gear Pump | 25&16 | ||||

| Valves | overflow and directional valves, OM/HUADE, Italy brand/China brand | ||||

| Main Oil Cylinder | Φ100*Φ70*1000mm | ||||

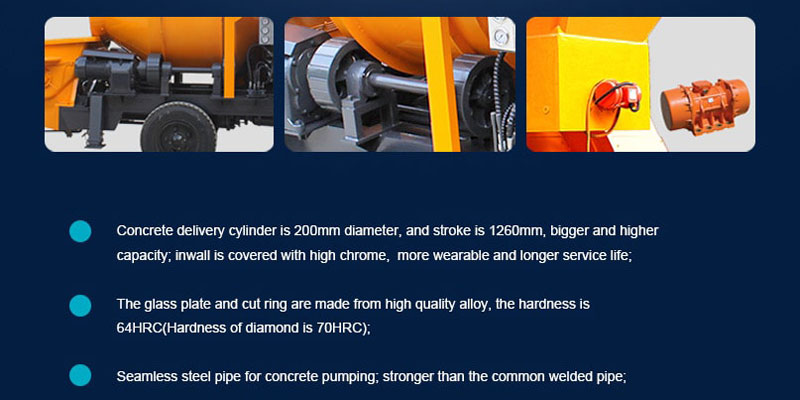

| Delivery Cylinder | Φ200*1000mm | ||||

| S Valve | Φ200mm | ||||

| Cutting Ring | Φ200mm | ||||

| Glass Wear Plate | Φ200mm | ||||

| Max. Theoretical Pumping Output | 40m³/h | ||||

| Outlet Pressure | 10Mpa | 6Mpa | 8Mpa | 10Mpa | |

| Hydraulic System Type | Open circuit | ||||

| Motor Rated Voltage | 380V, 3P | Diesel engine | Diesel engine | Diesel engine | |

| Max. Aggregate Size | Pebble:40mm Aggregate:30mm | ||||

| Delivery height and horizontal distance | 70m/300m | ||||

| Hydraulic Oil Tank Volume | 200L | ||||

| Concrete Outlet Diameter | Φ180mm | ||||

| Hopper Capacity × Filling Height | 600*1400 (L*mm) | ||||

| Machine Size(LxWxH) | 5100*2200*2450 mm | ||||

| Total Weight | 5600kgs | 5300kgs | 5600kgs | 5800kgs | |

| Tyre Size | 700R16 | ||||

| Towing Speed | Max. 8km/h | ||||

FAQ - More About Concrete Mixer Pump

Equipped with a JZM450 mixer drum on the basis of our trailer concrete pump. The JZM mixer drum is with 750L feed hopper that can each batch can produce 450L concrete. There are diesel engine type and electric motor type for customers to choose in HAMAC.

It is a trailer-mounted concrete pump equipped with a twin-shaft concrete mixer. Likewise, there are also diesel engine and electric motor for customers to select based on requirements. Equipped with twin-shaft mixer, the machine has higher production efficiency.

Concrete pump with mixer is suitable for the pumping of large aggregate concrete. It is suitable for construction sites with construction characteristics such as large amount of concrete pouring or narrow space. For example, some foundation piling construction, including rural civil construction, township and new rural construction, road and railway tunnels and other constructions in various caves, water conservancy and hydropower projects, geological disaster slope treatment, foundation Irrigation, etc.

When the concrete pump mixing machine is mixing, it generally needs to perform three times of mixing. Therefore, the mixed concrete is more uniform and of higher quality. It is more suitable for pouring construction with high floor quality requirements.

- Stir in the mixing tank. For the first time, concrete is mixed in a mixing bucket, which is the most important mixing process of concrete. Put shovel sand, pebbles, and cement into the upper hopper, and then transport them to the mixing drum from the upper hopper. The drum then quickly rolls to mix the concrete.

- Stir in the hopper. The discharge hopper is designed in an oblique arc shape, and the upper end is equipped with two mixing blades. After the concrete is mixed in the mixing drum, it will be introduced into the discharge hopper. After the concrete is mixed in the mixing drum, it will be introduced into the discharge hopper.

- Stir in the delivery pipeline. When the concrete is pumped to the pouring point by the delivery pipeline, it is rolled forward in a spiral manner in the pipeline, so that the concrete is also mixed, and the third mixing is completed.

Mixer pumps are special machines that operate continuously and can pump both dry mortar products or paste-like materials. The mixing pump can be manually fed with bagged material or automatically fed through the silo. In this case, the conveying system with spray hood ensures dust-free pneumatic feeding from the silo to the mixing pump. The conveying shaft feeds the dry material into the mixing tube, where the mixing screw treats the material with the necessary water in a processable pumpable mortar.

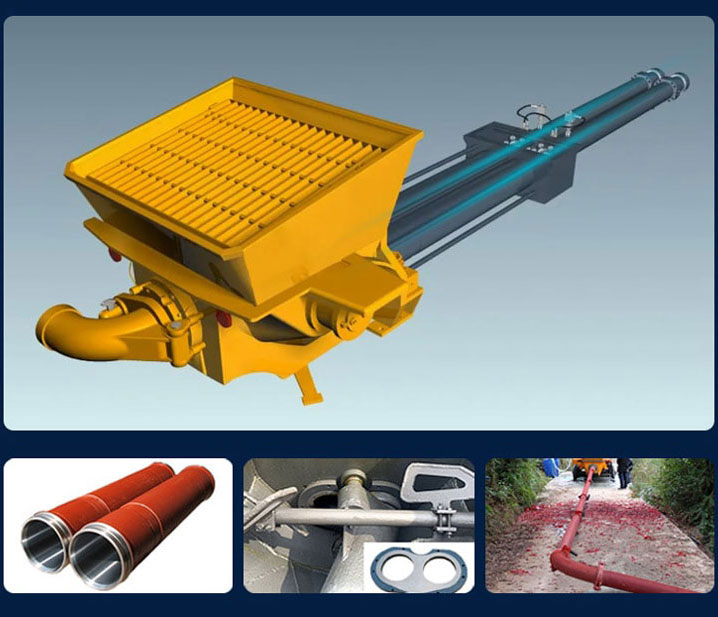

The machine drives the hydraulic pump through the motor. And the hydraulic pump drives the hydraulic cylinder to push the piston in the delivery cylinder to perform alternate movements of “one push and one suction”. The pistons are respectively connected to the piston rods of the main oil cylinder, and under the action of the hydraulic oil of the main oil cylinder, they reciprocate. When one cylinder advances, the other cylinder retreats. Continuous circulation, so as to realize the continuous pumping of the concrete mixing and pumping machine.

High pressure can satisfy long-distance transportation. Hydraulic cooling system, good water cooling effect, easy to use. With anti-jump function, it can minimize pipe clogging. Equipped with manual lubricating system, which guarantees the service life of the gearbox.

- Concrete conveying capacity, conveying height.

- Stirring efficiency of the mixer.

- The scale and duration of the construction site.

- If it is convenient to use electricity at the construction site. If there is no electricity supply, a diesel powered concrete mixer pump is required. If it is convenient to use electricity, you can choose an electric concrete mixer pump because it is cheaper.

- Concrete slump.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.