HAMAC Cement Silos for Sale

Cement silos are usually used as supporting equipment for concrete mixing plants. Meanwhile, they can also be sued alone for the storage of cement in some large-scale projects. The equipment is suitable for storing bulk cement and dry-made fly ash with the characteristics of rainproof, moisture-proof and easy to use. There are cement silos for sale with the capacity from to to 2000 tons in HAMAC. Customers can select according to their requirements.

- 50-2000 tons as options

- Famous brand accessories

- Fully customized as request

How Many Types of Cement Silos for Sale in HAMAC

According to whether it is convenient to move, the cement silos for sale can be usually divided into portable cement silo and fixed type cement silos. Meanwhile, it can be divided into horizontal cement silo and vertical cement silo.

Vertical Cement Silos

The vertical cement silos are a cylindrical structure, and the bottom is supported by four round tube legs. It is also known as bolted type cement silo. The bolted type cement silo is welded with steel structure, and a dust collector and a pressure relief valve are installed on the top of silo. This type is generally used as a supporting equipment for concrete batching plant.

Horizontal Cement Silos

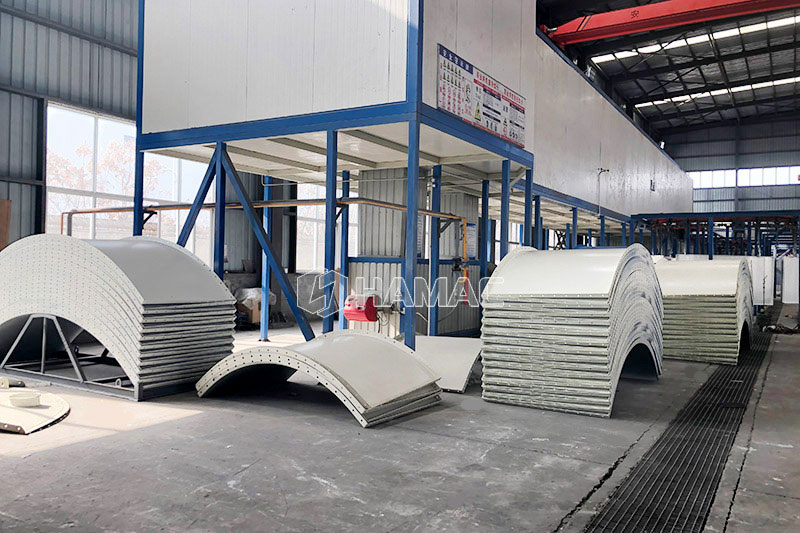

The horizontal cement silo is square in shape and the bottom is supported by several legs. This type of cement silo doesn’t need to install a foundation, so it can be regarded as portable cement silo. It is usually used in mobile mixing plants and foundation-free concrete mixing plants.

Bolted Cement Silos Specifications in HAMAC

| Model | Volume (T) | Diameter (mm) |

|---|---|---|

| 50T | 50 | 3260 |

| 60T | 60 | 3260 |

| 80T | 80 | 3260 |

| 100T | 100 | 3260 |

| 200T | 200 | 4200 |

| 300T | 300 | 4200 |

| 500T | 500 | 6600 |

| 600T | 600 | 6600 |

| 700T | 700 | 6600 |

| 800T | 800 | 6600 |

| 1000T | 1000 | 8000 |

| 1500T | 1500 | 10000 |

| 2000T | 2000 | 10000 |

How to Install Cement Silos

- Before the cement silo body is installed on site, the elevation of the two foundations of the equipment should be measured and leveled.For the fulcrum with large base error of the same warehouse body, the low point shall be raised according to the highest point elevation. The ultimate goal is to ensure that the center of the cement silo body is placed vertically, and its central axis must not be tilted.

- The main body of the cement silo is equipped with a process bracket when it is delivered, and it should be removed before installation.

- The components that can be assembled when the cement silo body is placed horizontally should be assembled as much as possible.After the silo body is erected and the anchor bolts are fixed, no personnel can move on the silo body to avoid danger.

- Due to the limitation of the feeding position and the ladder position of the storage bin and the batching bin, the orientations of the two devices relative to the base are slightly different. So attention should be paid during installation.

Maintenance Tips

- Frequently check whether the anchor bolts of the vibrating motor under the silo cone are loose. When it is found to be loose, it should be tightened in time, otherwise it will cause the vibration motor to fail.

- If the on-site air humidity is high, the warehouse roof dust collector is equipped with a damp air blocking device at the air outlet to minimize the impact of moist air on the dust removal system.However, it should still be checked every month whether the air outlet system of the dust collector on the warehouse roof is unobstructed, and whether the filter bag is sticky or hardened.

- When there is a control action error or failure, it should be repaired by professional electrical personnel. Other personnel without operating qualifications are not allowed to open the inner cover of the operation box.

Content Index

What Are Advantages of Bolted Cement Silo

The bulk cement silo is a closed tank for storing bulk materials, suitable for storing various bulk materials such as grain, cement, and fly ash.

It has the characteristics of waterproof, moisture-proof, preventing cement loss, reducing urban air dust pollution, small footprint, long service life and low cost.

Equipped with a material level system, which can display the position and quantity material. The hole-breaking device can relieve the solidity caused by the long-term deposition of the material. The cement silo and the screw conveying pump can be used together to convey the material to various locations.

The silo body is easy to install, safe and reliable, and is an ideal bulk storage equipment for various mixing plants.

A variety of cement silos for sale with different specifications and capacities as options for customers.

Cement silos are used to store bulk cement, fly ash and other construction materials pneumatically transported by sealed tank trucks. The cement is transported to the batching bin through the pneumatic ash pump under the storage bin, and quantitatively fed to the batching equipment through the conveyor belt conveyor below.

What Are Bolted Cement Silo Accessories

Bolted type cement silo is composed of the steel structure of silo body, ladders, guardrails, feeding pipes, dust collectors, pressure safety valves, high and low material level gauges and discharge valves.

Dust removal system. The top of the cement silo is equipped with an electric dust removal device, which can effectively absorb suspended particles in the silo and reduce pollution to the surrounding environment.

Arch breaking device. The lower cone of the cement silo is equipped with an air blowing arch breaking device, which uses a small electromagnetic reversing valve in the air control box to control the release of compressed air to break the arch of cement and various powder materials to avoid powder accumulation and blockage.

Material level device. The cement silo material level device can sense the storage height of the material in the silo.

Get Price of Cement Silos for Sale in HAMAC - Reliable Cement Silo Manufacturer

HAMAC can supply cement silos with storage capacity ranging from 50 tons to 2000 tons. At the same time, the height and diameter of the cement silo for sale in our company can be customized. Cement silo prices vary by types and capacity. So please contact us tell us the following details for the exact quotation.

- Cement silo capacity you need. If you are not sure, you can also tell us the project type, project size and other factors, and our engineer will give you the most professional advice.

- The diameter and discharge height of cement silos. For that the support leg length will be different, as well as the different cost.

- The configuration of accessories will also affect cement silos price. You can tell us your budget, we will configure the most cost-effective cement silos for you.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECH Industrial Development Zone, Zhengzhou,China.