Concrete Mixer Truck for Sale

Concrete mixer truck is a special truck equipped with a cylindrical mixing drum to transport mixed concrete for construction. Usually, Concrete mixer truck for sale with different capacities can be selected according to different situations such as the length of concrete transport distance, site construction conditions, and requirements for the proportion and quality of concrete.

- 4-12m3 drum as options

- Famous brand hydraulic parts

- Famous brand chassis as options

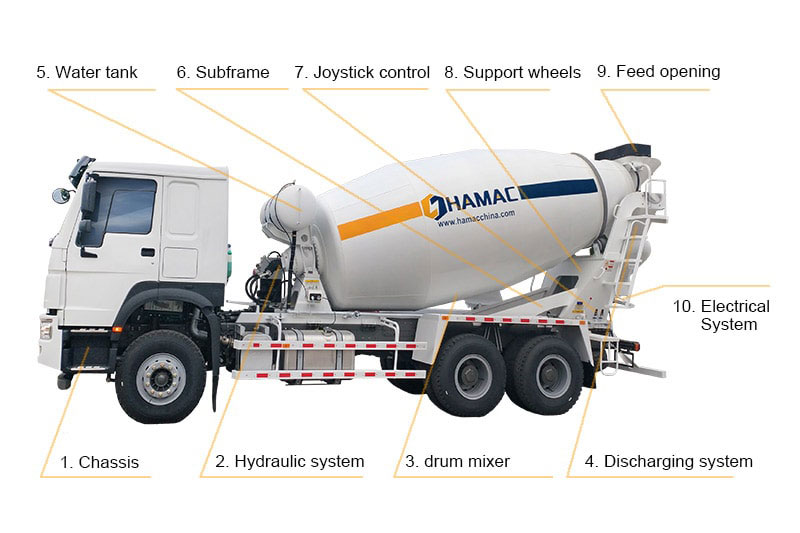

What Is Concrete Mixer Truck

Concrete mixer truck is actually a combined machine that installs a unique concrete mixing device on a truck or a special carrier chassis. It has the functions of transporting and mixing concrete, which can realize mixing while transporting concrete. During transportation, the mixing drum will always be kept rotating to ensure that the carried concrete will not solidify. Therefore, it can guarantee the quality of conveyed concrete and extend the delivery time appropriately. After the concrete is delivered, the inside of the mixing drum is usually washed with water to prevent the hardened concrete from taking up space.

Why Buy Concrete Mixer Truck For Sale in HAMAC

Famous brand truck chassis. We have strong and long-term cooperative relationship with SHACMAN, SINOTRUK, FOTON, etc., So that we can guarantee the most competitive price, high quality and delivery time.

Famous brand hydraulic parts and gearbox. First, high performance can be guaranteed. Second, we provide customers with a 3-year warranty for these three key components.

4-12m3drum as options. Customers can choose the required type of mixer truck according to the needs of construction.

Excellent service. HAMAC has a dedicated technical team to provide customers with complete solutions for commercial ready mix concrete batching plant business.

Factory direct sales, with rich production experience. We have good cooperative relations with manufacturers of major components, so we can ensure the most competitive concrete mixer truck price.

Technical Parameters of Concrete Mixer Truck For Sale in HAMAC

| Item | Details | 4m3 | 6m3 | 8m3 | 10m3 | 12m3 |

|---|---|---|---|---|---|---|

| Chassis | model/Brand/Origin | (YUEJIN, WAW, FORLAND ETC) | HOHAN, CDW | SHACMAN, HOWO | ||

| Chassis-driven model | 4×2 | 4*2 | 4*6 | 4*6 | 4*8 | |

| Mixing drum | Agitating capacity (m3 ) | 4.9 | 6.0 | 8.0 | 10.0 | 12.0 |

| Residual rate (%) | ≤0.5% | |||||

| Feeding rate (m3/ min ) | ≥3 | |||||

| Charging rate (m3/ min ) | ≥2 | |||||

| Inclination angle of drum | 15 (Customized) | |||||

| Hydraulic System | Pump model/brand | SUNNY | SUNNY | ARK | ARK | ARK |

| Motor model/brand | SUNNY | SUNNY | ARK | ARK | ARK | |

| Reduction gear | RONGJIAO | RONGJIAO | TOP | TOP | TOP | |

FAQ - More About Concrete Mixer Truck Machine

Power take-off device. Adopt the main vehicle engine power take-off method. The function of the power take-off device is to take out the engine power by manipulating the power take-off switch, and drive the mixing drum through the hydraulic system. The mixing drum rotates in the forward direction during feeding and transportation to facilitate feeding and mixing of concrete. It rotates in the opposite direction when discharging, and cuts off the power connection with the engine after the work is completed.

Hydraulic system. The engine power taken out by the power take-off device is converted into hydraulic energy, and then output by the motor as mechanical energy to provide power for the rotation of the mixing drum. After decelerating the output speed of the motor in the hydraulic system, it is transmitted to the mixing drum.

Reducer. After decelerating the output speed of the motor in the hydraulic system, it is transmitted to the mixing drum.

Control mechanism. Control the rotation direction of the mixing drum so that it rotates forward during feeding and transportation, and rotates reversely during discharging. At the same time, control the rotating speed of the mixing drum.

Stirring device. The mixing device is mainly composed of a mixing drum and its auxiliary supporting parts. The mixing drum is a container for loading concrete. When rotating, the concrete moves along the helical direction of the blade, and is mixed and stirred during the process of continuous lifting and turning. During feeding and transportation, the mixing drum rotates forward, and the concrete moves inward along the blades. When discharging, the mixing drum reverses, and the concrete is discharged outward along the blades.

Cleaning system. The main function of the cleaning system is to clean the mixing drum. Sometimes it is also used for dry material mixing drum and cleaning system during transportation. And it also plays a role in cooling the hydraulic system.

The power is output by the full-power power take-off device of the second type chassis. The power is transmitted to the hydraulic pump through the transmission shaft. The hydraulic pump generates hydraulic energy and transmits it to the hydraulic motor through the oil pipe. The hydraulic motor converts the hydraulic energy into kinetic energy and transmits it to the mixing tank through the reducer to reduce the speed and increase the torque. By adjusting the angle of the handle of the hydraulic pump, the forward and reverse rotation of the mixing tank and the size of the rotating speed can be realized, so as to realize the operations of concrete charging, stirring, stirring, and discharging.

In terms of volume, the common ones in the market are 2 m³, 3 m³, 4 m³, 5 m³, 6 m³, 8 m³, 10 m³, 12 m³, 14 m³, 16 m³, 18 m³, and 20 m³. 3-6 squares truck are mainly used in some narrow venues, areas where turning are inconvenient. 8-12 squares mixer truck are the mainstream in the market and are used more.

In terms of chassis, it can be divided into vehicle chassis and semi-trailer chassis. The semi-trailer chassis truck mixer has a heavy load and is mainly used for large-volume tanks, but its turning radius is more limited.

According to the moisture content of the concrete shipped by the concrete mixer truck, there are three kinds of mixer trucks, wet material type, dry material type and semi-dry material type.

Wet material concrete mixer truck. It can transport concrete produced by the mixing plant or aggregate, cement and water mixed in proportion. During the transportation process, the wet material is continuously stirred slowly to prevent the initial setting and segregation of the concrete during transportation. However, the time from production to pouring of concrete should generally not exceed 1.5 hours to prevent the concrete from setting. Therefore, in the case of longer distance transportation, it is necessary to use dry and semi-dry material mixer trucks to transport.

Dry material mixer truck. The mixer truck can directly load the dry aggregate and cement into the mixing drum of the truck according to the ratio. The dry material in the barrel is mixed during transportation. And when the vehicle is about to arrive at the construction site or add water at the construction site to complete the mixing of concrete.

Semi-dry material truck mixer. The aggregate and cement in the concrete shipped by the semi-dry mixer truck are also prepared according to the ratio and contain a certain amount of water. But the water content doesn’t meet the pouring requirements. So it is necessary to add water and stir when the concrete mixer truck is about to reach the construction site or at the construction site.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.