What Is A Concrete Transit Mixer

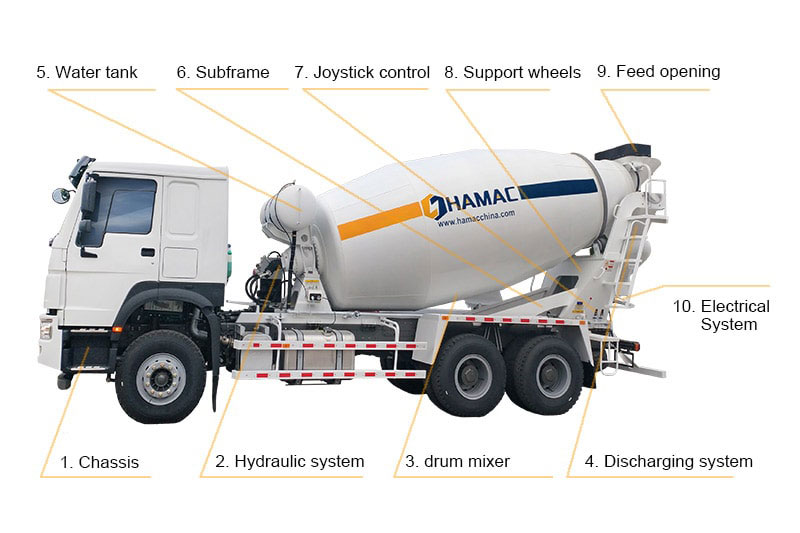

Concrete transit mixer is the necessary concrete equipment used to transport the concrete produced by the concrete batch plants to the construction sites. The mixing drum is installed on a car chassis. It will keep rotating during the transportation process to ensure the concrete is always in a mixing state and prevent the concrete from agglomerating during the transportation process. Transit mixer can not only improve work efficiency, reduce the workload of personnel, but also ensure high-quality use of concrete.

Why Do You Need Concrete Transit Mixer

In order to obtain the best concrete ration, quality, and reduce the occupation of the construction sites. At the same time, in order to improve the construction progress and shorten the construction period, concrete has evolved from on-site mixing to more advanced professional concrete production and transportation.

If the transit concrete mixer doesn’t mix, the stones in the concrete will sink into the bottom layer during transportation, the middle layer is sand, and the upper layer is cement slurry, and there will be agglomeration after being transported to the construction sites. Therefore, the rotation of the mixer transit truck during transportation can not only prevent the concrete from agglomerating, but also prevent the concrete from stratifying. So that the sand, stone and cement in the concrete can be mixed more evenly.

After the transit mixer is loaded, there is still a relatively long transportation distance from the concrete production sites to the construction sites. In order to prevent the concrete from caking during transportation, a certain amount of retarder is generally added to the concrete formula.

Capacity of Transit Mixer Drum

A mixer drum is a cylindrical container equipped on the concrete transit mixer. It is responsible for transporting and mixing concrete during transportation. The capacity of a drum is the volume of concrete it can hold, usually measured in cubic meters. The capacity of transit mixer drums is a key factor to consider as they determine the amount of concrete that can be transported and mixed in one shipment. Choosing the right drum capacity is critical to optimizing productivity, reducing costs and ensuring smooth running of your construction site.

Technical Parameters of Concrete Transit Mixer for Sale

| Model | HZS-25 | HZS-35 | HZS-50 |

|---|---|---|---|

| Theoretical Productivity (m³/h) | 25 | 35 | 50 |

| Mixer Discharging Volume (L) | 500 | 750 | 1000 |

| Mixer Feeding Volume (L) | 800 | 1200 | 1600 |

| Mixer Motor Power (KW) | 18.5 | 30 | 18.5×2 |

| Discharging Height (m) | 3.8 | 4.1 | 4.1 |

| Aggregate Material Quantity (m3) | 3×3 | 5×3 | 8×3 |

| Cycle Period (s) | 72 | 72 | 72 |

| Max. Aggregate Size (mm) | 80/60 | 80/60 | 80/60 |

| Cement Silo (t) (optional) | 50×1 | 50×1 | 100×1 |

| Aggregate Weighing Accuracy | ±2% | ±2% | ±2% |

| Powder Material Weighing Accuracy | ±1% | ±1% | ±1% |

| Water Weighing Accuracy | ±1% | ±1% | ±1% |

| Additive Weighing Accuracy | ±1% | ±1% | ±1% |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 |

| Control Mode | Full Automatic Computer PLC Control | Full Automatic Computer PLC Control | Full Automatic Computer PLC Control |

| Power Supply | 220V/415V/440V/380V/, 50HZ/60HZ, 3Phase | 220V/415V/440V/380V/, 50HZ/60HZ, 3Phase | 220V/415V/440V/380V/, 50HZ/60HZ, 3Phase |

What Is Transit Mixer Used For

The main purpose of the concrete transit mixer is to transport the concrete or mortar that has been mixed in the concrete mixer to the construction site. Transit mixer truck are mostly used in the construction of commercial mixing stations and large-scale projects. The construction sites must be equipped with an overhead concrete mixer that allows mixer trucks to pass freely and receive materials. In addition, the concrete transit mixer also can transport the same amount of water as the load concrete. The mixer drum of the transit mixture machine can be rotated and stirred at an adjustable speed. Therefore, the use of mixer trucks to transport concrete can ensure that there is no segregation within the specified distance and time, the coarse aggregate does not settle, and good workability is maintained.

Content Index

How To Choose the Right Types of Transit Mixer for Sale in HAMAC

The nature and scale of the construction project. For smaller projects, a transport mixer with a smaller drum capacity can be selected. Infrastructure development large-scale projects often require higher concrete volumes, necessitating the selection of transport mixers with larger drum capacities.

Demand for concrete. High-demand projects with tight schedules require larger drum capacities to transport more concrete, thereby increasing the efficiency of concrete transport. Conversely, projects with low concrete demand can choose a smaller drum capacity to avoid unnecessary cost increases.

Analyze the construction sites. The space, access and topography of a construction site all affect the choice of transport mixer drum capacity. For sites with limited space, narrow access, or remote areas where walking is inconvenient, transit mixer trucks with smaller drum capacities and volumes are more appropriate as they provide enhanced mobility and flexibility.

Construction efficiency and budget. If the drum capacity is too small for the project requirements, it may result in frequent trips, thereby increasing transportation costs and delaying the construction period. Conversely, using a drum with a larger capacity than necessary results in underutilization and increased costs.

Therefore, choosing the right model can maximize productivity, reduce costs and ensure smooth operation during concrete transportation and mixing.

Working Principle of Concrete Transit Mixer

Principle of stirring function

The power take-off drives the hydraulic motor of the hydraulic pump to rotate through the small transmission shaft, and drives the mixing barrel to rotate through the reducer. In the process of concrete transportation, it is necessary to keep the mixing tank rotating at a low speed of 1-3rpm to ensure the uniformity of the concrete and prevent concrete segregation.

Principle of charging function

When the mixer truck is loaded with concrete, the speed of the mixing tank is relatively high, 6-10rpm. The concrete enters the mixing drum from the nozzle through the feeding system, and flows to the middle and lower part of the mixing drum under the guidance of the spiral blade. The direction of rotation of the tank body should be consistent with the direction of rotation during transportation, otherwise the concrete will be unloaded during transportation.

Principle of unloading function

When the transit mixer is unloading, the engine transmits power to the mixing tank through the power take-off, hydraulic pump, reducer, etc. And drive the tank to rotate at a speed of 3-14rpm. Driven by the helical movement of the concrete blades, the concrete blades move toward the mouth of the barrel and are discharged through the hopper of the mixer truck. At this time, the rotation direction of the tank body is opposite to the feeding direction.

Principle of cleaning function

The water tank is pressurized by the cylinder of the brake system, and the water flows through the pressurized cleaning mixing tank system, the feeding port, the discharging system, etc.

How Is the Transit Mixer Price

Drum capacity. The additional material, manufacturing complexity, and construction required to produce larger volume drums tend to command a higher price for larger capacity drums.

Car chassis. Factors such as manufacturer, models, engine power, transmission type, suspension system, and additional features all affect the transit mixer price.

Technology and accessories for equipment. Advanced manufacturing processes, high-quality materials, and the use of accessories from different brands will all affect price changes.

Choosing a good brand can not only guarantee the high quality, reliability, durability, and long-term performance of the concrete transit mixer. At the same time, it can also guarantee better after-sales service. As a professional transit mixer manufacturer, HAMAC can guarantee the most competitive concrete transit mixer price.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.