What Is Cone Crusher

Cone crusher is a crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical and silicate industries. According to different crushing principles and product particle sizes, it is divided into many models. The cone crusher has a large crushing ratio, high efficiency, low energy consumption and uniform particle size. It is suitable for medium and fine crushing of various ores and rocks. It is a continuous operation and high-efficiency crushing equipment. The cone crusher is also suitable for crushing hard and medium-hard ores and rocks, such as iron ore, limestone copper ore, quartz, granite sandstone, etc.

Types of Cone Crusher for Sale in HAMAC

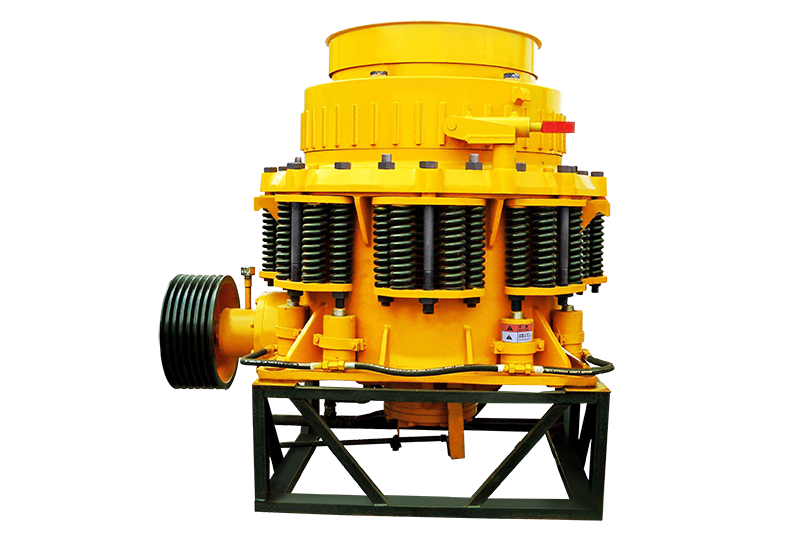

Single Cylinder Cone Crusher

- Full hydraulic design

- Excellent final product shape

- Small volume but high efficiency

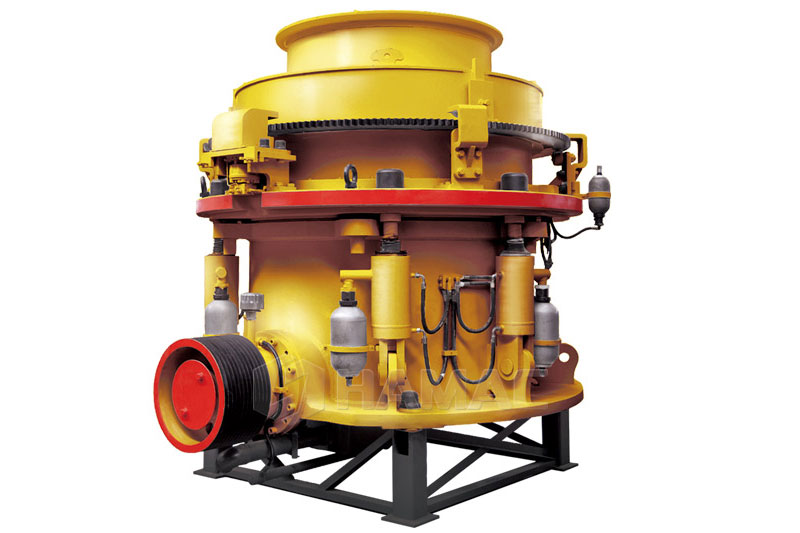

Multi Cylinders Cone Crusher

- High efficiency

- Large production capacity

- High-quality aggregate

- More stable operation

Compound Cone Crusher

- High efficiency

- Multiple crushing cavity types

- Dry oil seal and dustproof

- More stable operation

S Series Spring Cone Crusher

- High cost performance

- Big crushing ratio

- Small volume but high efficiency

How To Choose The Suitable Cone Crusher For Sale in HAMAC

- Production capacity of cone crusher. The specifications and models of the equipment are the key factors affecting the production capacity of the cone crusher. And the cone crushers produced by different manufacturers are different in terms of speed, meshing angle, spindle eccentricity and feed inlet size, which determine the processing capacity of the equipment. Therefore, please carefully know about the production capacity of each model and specification when purchasing.

- Actual production demand.According to the actual production situation of your own company, decide to choose which type of cone crusher. It is generally recommended that enterprises with large production scale and high hourly production requirements can choose large cone crusher equipment, which can not only improve efficiency but also increase output. For small enterprises or enterprises with less strict requirements on time production and income, it is recommended to choose cone crushers and relatively small ones to save costs and reduce losses.

- Price. The prices of different manufacturers vary due to factors such as research and development, production and manufacturing cost input. So users should choose multiple manufacturers when purchasing cone crusher equipment, compare quotations in order to ensure quality and quantity. Then choose equipment with high cost performance.

- Consider operating costs.The main operating costs of the cone crusher after it is put into use include the consumption of wearing parts and materials, as well as power consumption. Choose the machine with low running consumption.

- The strength of cone crusher manufacturers.As a leading and reliable cone crusher manufacturer, we can provide various specifications and types of crusher equipment. Both product quality and price can be guaranteed. Feel free to inquiry us for the best cone crusher price now, we will reply in 24 hours.

FAQ - More About Cone Crushing Machine

The structure is simple, the manufacturing cost is low, and the performance is stable. It is suitable for medium, fine and even ultra-fine crushing operations. The single-cylinder hydraulic cone crusher has a large spherical radius of the movable cone support, a small eccentric angle of the main shaft, and a long crushing cavity, which improves the uniformity of the crushed material.

The equipment is characterized by high swing frequency, large eccentricity, slow taper, multi-cylinder hydraulic locking around, and the main shaft is supported by cantilever beams and spherical tiles. The hydraulic motor is used to adjust the fixed cone, which has a large crushing force and is suitable for crushing hard materials. However, due to the small radius of the spherical surface of the multi-cylinder cone crusher, the radius of the pendulum is small, and there are unstable phenomena such as shaking of the moving cone, overturning and speeding. At the same time, there are also problems such as poor contact between the main shaft and the bushing, and large impact force.

This equipment is suitable for the fourth-stage crushing of medium-hard materials. It is characterized by its special crushing cavity shape, which can realize lamination crushing, and can obtain smaller product particle size under the condition of larger discharge opening. The disadvantages of this machine are high energy consumption, bulky machine and low output. With the increasingly high-energy development of cone crushers, this machine will gradually be replaced by hydraulic cone crushers.

A new type of ultra-detail energy crushing equipment, which has a good effect of “material layer crushing”. The particle size of the open-circuit crushing products is millimeter-level, which can meet the requirements of the new process of “more crushing and less grinding”, and greatly reduce the energy consumption and steel consumption of the crushing and grinding process. However, this machine also has its own shortcomings, that is, it is too bulky, and the weight of the machine is about twice that of other cone crushers.

The equipment is mainly used as a medium and fine crusher. Because of its low price, relatively stable performance, and widespread experience in user maintenance, it is the most commonly used cone crusher in the world at present when it is used in occasions that do not require high product particle size. However, the force on the main shaft of this machine belongs to the cantilever beam, which makes its structure much bulkier than the single-cylinder hydraulic cone crusher of the same specification, and the crushing force is small, the output is low, and the iron passing function is not reliable. This machine will gradually be replaced by a hydraulic cone crusher with high-energy laminated crushing.

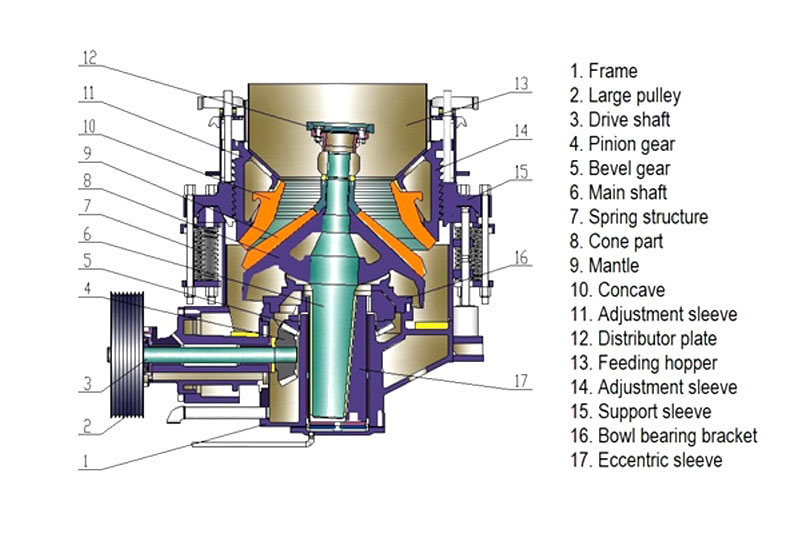

The cone crusher is mainly composed of a frame, crushing parts, transmission parts, adjustment and locking devices, safety devices, feeding devices, dust-proof devices, and lubrication systems.

Crushing plants. Composed of fixed cone, fixed cone liner, movable cone for crushing materials, moving cone, moving cone liner, main shaft.

Transmission device. Composed of motor, coupling, large and small gears. The function of the eccentric sleeve is to convert the rotary motion of the motor into the rotary pendulum motion of the moving cone after deceleration.

Discharge opening adjustment and locking device. Composed of adjusting sleeve, supporting sleeve, locking sleeve.

Dust cover function. Adjust and lock the discharge port.

Safety device: spring set.

Feeding device. Composed of feeding hopper, feeding box, distribution plate.

Lubrication system. The thread lubrication between the adjustment sleeve and the support sleeve adopts manual lubrication and regularly injects grease. The transmission shaft and the bearing are lubricated separately with thin oil. Eccentric sleeves, push bearings, spherical bearings, and bevel gears are lubricated by thin oil circulation.

Dustproof device. Spherical bearings, dustproof for large and small bevel gears. Dust protection of support sleeve and locking sleeve.

The crushing process is completed between the fixed cone and the rotating moving cone. When the cone crusher is working, the horizontal shaft of the crusher is driven by the motor through the V-belt and the pulley. The horizontal shaft drives the eccentric sleeve to rotate through the large and small gears. Under the action of the eccentric sleeve, the cone shaft of the crusher produces eccentricity and performs a pendulum motion, so that the surface of the crushing wall is sometimes close to the surface of the fixed cone, and sometimes away from the surface of the fixed cone. So that the stone is continuously crushed, broken and impacted in the crushing cavity. The crushed material is discharged from the discharge port at the lower part of the crusher under the action of its own weight.

The upper cavity of the cone crusher motor cone is supported on the spherical bearing pad at the upper end of the fixed main shaft, and the lower cavity is set outside the eccentric bushing, and its movement is directly driven by the eccentric bushing. When the eccentric sleeve rotates around the main shaft, the moving cone not only rotates around the center line of the machine with the eccentric sleeve, but also rotates around its own axis. The axis of the moving cone intersects the center line of the main shaft at a fixed point, that is, the center point of the sphere, and the included angle is the precession angle. When the crusher is running, the axis of the moving cone moves on a conical surface relative to the center line of the machine, and the top of the cone is the center of the spherical support, which remains static during the movement of the moving cone. Therefore, the motion of the moving cone can be regarded as the rotation of a rigid body around a fixed point.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.