Fly ash brick making machine For Sale

Fly ash brick making machine is an environmentally friendly brick making machine with fly ash as the main raw material. It takes fly ash or other slag, lime sand as raw materials, adds lime, gypsum and aggregate. Fly ash brick machine is the main equipment for producing fly ash autoclaved bricks through blank material preparation, compression molding, high-efficiency steam curing and other processes. HAMAC can provide fully-automatic, semi-automatic, hydraulic fly ash brick machines with different models. Contact us for technical support now.

Excellent Performances of Fly Ash Block Making Machine

High production capacity. The body of the fly ash brick making machine is made of heavy-duty steel structure. The split design can prolong the service life of the equipment. The performance is stable and reliable. The small oil cylinder in the middle makes the upper die head rise and fall quickly. Equipped with a special palletizer, it can easily realize large-volume automatic production.

The bricks produced are of high quality and consistent size. Equipped with advanced technology and automated process, it can produce bricks with uniform size, smooth surface and precise edges. The use of a hydraulic system ensures accurate compaction and compaction strength, giving the brick excellent structural integrity.

Advanced configuration. The fly ash brick making machine for sale in our company adopts imported PLC intelligent control, adopts internationally renowned hydraulic components. And the technical parameters can be adjusted at any time. When the machine is misoperated, it can promptly and accurately notify the user of the fault and the treatment method. The production of various types of bricks can achieve ideal molding effects, high density and high strength.

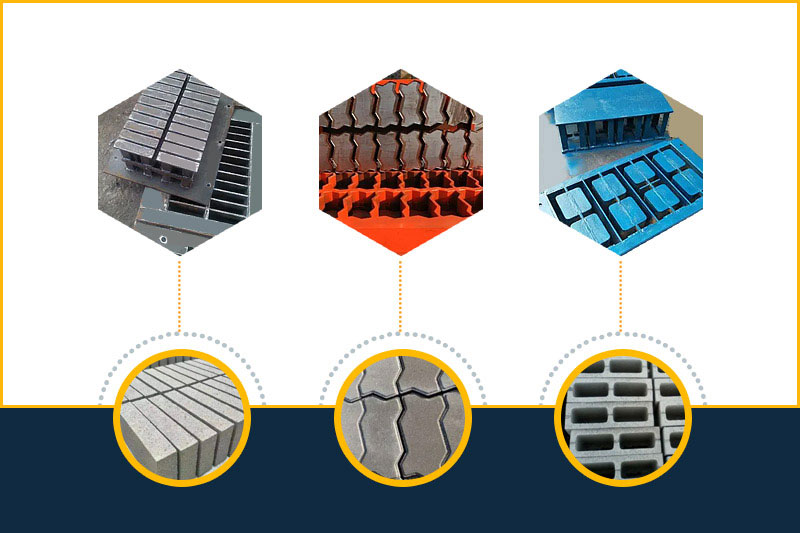

Prepare bricks of various sizes. The fly ash brick making machine can be adjusted and customized to make different types and sizes of bricks including solid bricks, hollow bricks, interlocking bricks and more. The equipment can meet the requirements of different construction requirements and building preferences.

Energy saving and environmental protection. Our fly ash brick making machines are designed to be energy efficient and minimize energy consumption during the brick making process. Not only can it help save costs, but it can also contribute to environmental sustainability by reducing carbon emissions.

What is the size of fly ash bricks machine

Our company can provide different specifications of fly ash brick making machines. Each is designed to meet different production requirements. At the same time, customers can also choose a fully automatic fly ash brick machine, semi-automatic flyash brick machine or manual fly ash brick making machine. In addition, machine production capacity is also another key factor to consider when choosing the model of fly ash brick making machine.

Brick making machines are usually equipped with molds of different specifications and sizes to meet the needs of customers for making different types of bricks.

Technical Parameters of Fly Ash Brick Machine

QT4-15 Main technical parameters:

| Dimension | 3600×1800×2600mm | Motor Power | 29.4KW |

| Mould Area | 550×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×550×30mm | Weight Of The Block Making Machine | 5800kgs |

QT5-20 Main technical parameters:

| Dimension | 3650×2100×2720mm | Motor Power | 20KW |

| Mould Area | 550×1100mm | Vibration Force | 50KN |

| Working Cycle | 16-25S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 1100×550×30mm | Weight Of The Block Making Machine | 6000kgs |

QT6-15 Main technical parameters:

| Dimension | 4410×2000×2510mm | Motor Power | 36.4KW |

| Mould Area | 680×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×680×30mm | Weight Of The Block Making Machine | 6000kgs |

QT8-15 Main technical parameters:

| Dimension | 4900x2120x2650 mm | Motor Power | 46.4KW |

| Mould Area | 850×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 900×850×35mm | Weight Of The Block Making Machine | 6500kgs |

QT10-15 Main technical parameters:

| Dimension | 7500x2500x3020 Mm | Motor Power | 50.88KW |

| Mould Area | 1220×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 1220×900×35mm | Weight Of The Block Making Machine | 7000kgs |

Production Process of Fly Ash Brick Making Machine

The production process of flyash block machine includes several major steps such as processing and preparation of raw materials, metering and batching according to a certain proportion, mixing, wheel milling, pressing and forming, autoclaving maintenance, bricks inspection and stacking.

Batching. The batching system needs to use belt conveyors, electronic batching machines, forced mixers, and conveyors. Transport lime and gypsum to the electronic batching machine by conveyors according to the process amount. At the same time, send the fly ash and aggregate to the forced mixer through the belt conveyor in a certain proportion. After adding water and stirring, it is sent to the wheel mill.

Brick molding. The adobe forming system consists of a belt conveyor, a hydraulic brick machine and an automatic adobe stacking machine. The mixed material after wheel grinding is sent to the feeding mechanism of the brick press with a belt conveyor, and pressed into shape.

Autoclaved curing. The formed adobes are stacked on the maintenance trolley, and the trolley is sent to the static kiln for grouping and stopping. The static stop is to allow the adobe to reach a certain strength before autoclaving, so that it can resist the stress caused by temperature changes during autoclave curing and prevent the adobe from cracking.

What material is required for making fly ash bricks

- Fly ash. When mixed with other materials, fly ash acts as a binder that helps increase the brick’s strength and durability. It is the dust and bottom slag collected from the flue gas of coal-fired boilers and the desulfurization ash produced in the production process of coal-fired power plants. In terms of resource utilization, fly ash is a solid waste. Because fly ash contains sulfide and dust, it has a great negative effect on acid rain and air pollution. Therefore, the appearance of fly ash brick making machine has a certain containment effect on fly ash pollution to a certain extent.

- Cement. Cement is an important component of fly ash bricks, providing cohesion and stability to the brick structure. When it combines with fly ash, its binding properties create a chemical reaction that forms a solid matrix. Cement plays a key role in ensuring the structural integrity of the brick.

- Sand. As filler material, sand is the basic ingredient in the production of fly ash bricks. It helps improve the workability of the mixture and helps create a uniform texture. The presence of sand increases the compressive strength, making them easier to handle during construction.

- Water. Water plays a vital role in causing the bricks to harden as the medium that activates the cement and fly ash mixture. Proper water content is critical to achieving the desired consistency and workability of fly ash brick mixtures.

Start A Brick Making Business Now

As an available resource, fly ash has been widely used in many fields such as building materials, construction engineering, road construction, agriculture, and high-performance ceramics. Fly ash bricks are popular in the construction industry for their environmental sustainability and cost-effectiveness.

If you are planning to start a brick making business and want to buy the right brick making machine. We can provide you with technical support. Tell us more about your requirements, such as, your local market, budget, raw materials, etc. We will help you choose a suitable model, recommend the best design for you, and guarantee to provide you with the most competitive price fly ash brick making machine.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.