Hollow Block Machine For Sale

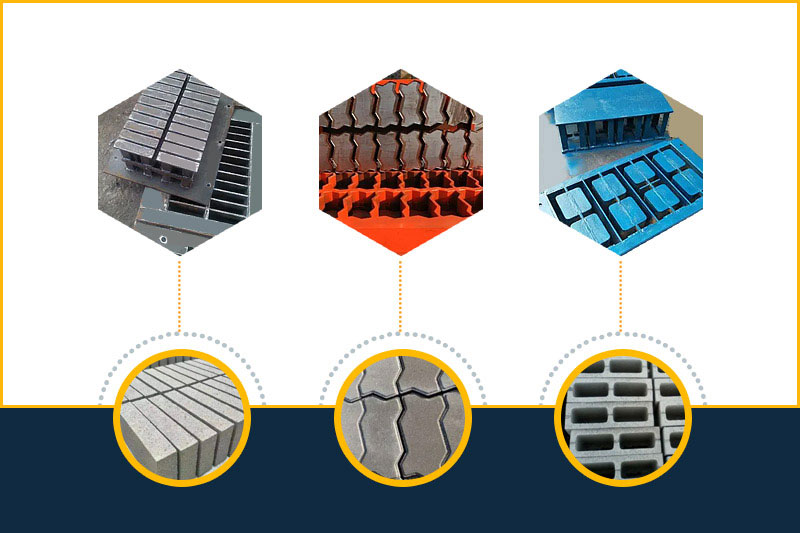

Hollow block making machine have different molds for the shape of concrete blocks. When the mortar is poured into these molds, a machine will use vibration and hydraulic pressure to force the mortar into the mold.

- Mobile and stationary type as options

- Fully automatic controlled by software

- Various models for different capacity

What Is Hollow Block Machine

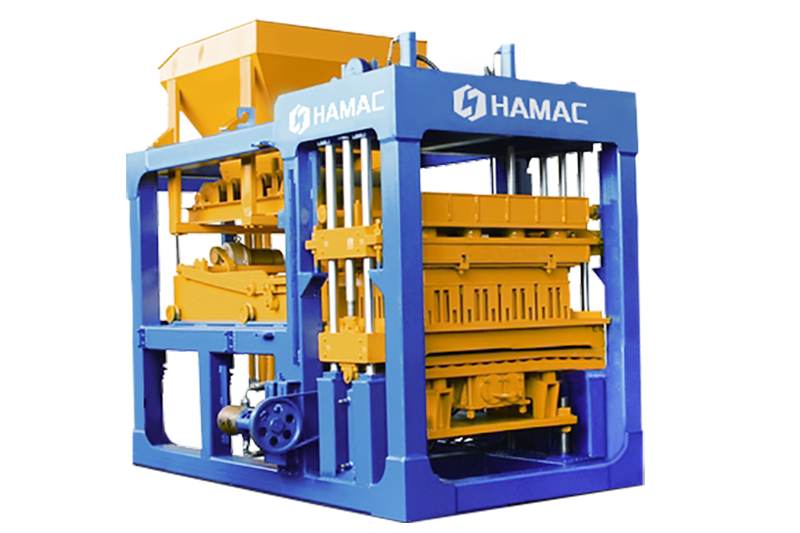

The reason why this kind of concrete brick making machine is called hollow block machine is because of the mold. In this way, the concrete hollow blocks are formed. This kind of equipment can produce hollow bricks of different specifications by changing the molds, and can produce almost any type of blocks used in construction. Hollow bricks machine is a mechanical equipment that adds cement to fly ash, construction waste, slag, coal gangue, river sand and stones to produce hollow bricks. And the hollow block machine is a new type of wall materials, which is environmentally friendly, economical and effective. Hollow block machine for sale in HAMAC has been well received by our customers.

What Are Excellent Performance of Hollow Block Machine for Sale in Our Company

- The human-machine interface adopts a visual and humanized design mode, and the technical parameters can be adjusted at any time. Through technical breakthroughs, scientific research personnel use high-tech technical means to integrate the oil circuit, gas circuit, circuit and machinery of the whole machine, so that the entire production line can run periodically by itself.

- The machine body is made of super strong material and special welding technology, which is extremely strong and durable. The machine body is made of super strong material and special welding technology, which is extremely strong and durable.

- The material distribution system adopts the automatic operation mode of guided retesting, the structure is stable and reliable. And it is highly targeted and crushing for different products, so as to achieve the best material distribution effect and make the product density uniform.

- Hollow bricks of different strengths and shapes can be produced. Our equipment can produce bricks of different strength grades according to the requirements of engineering construction. Different design specifications such as the size of hollow blocks, cement bricks, and paving bricks can be determined according to engineering needs. It can also be used to produce different types of concrete bricks such as hollow blocks, multi-row bricks, solid bricks, paving bricks, decorative bricks, wall bricks, etc.

- Waste concrete bricks can also be recycled to increase the comprehensive utilization of resources. We can also design the hollow block factory for you according to the land you own.

Models of Hollow Block Machine for Sale in HAMAC

QT4-15 Automatic concrete brick forming machine Main technical parameters:

| Dimension | 3600×1800×2600mm | Motor Power | 29.4KW |

| Mould Area | 550×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×550×30mm | Weight Of The Block Making Machine | 5800kgs |

QT5-20 Automatic concrete block forming machine Main technical parameters:

| Dimension | 3650×2100×2720mm | Motor Power | 20KW |

| Mould Area | 550×1100mm | Vibration Force | 50KN |

| Working Cycle | 16-25S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 1100×550×30mm | Weight Of The Block Making Machine | 6000kgs |

QT6-15 Automatic concrete brick machine Main technical parameters:

| Dimension | 4410×2000×2510mm | Motor Power | 36.4KW |

| Mould Area | 680×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS500 |

| Size Of The Pallet | 900×680×30mm | Weight Of The Block Making Machine | 6000kgs |

QT8-15 Automatic hydraulic block making machine Main technical parameters:

| Dimension | 4900x2120x2650 mm | Motor Power | 46.4KW |

| Mould Area | 850×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 900×850×35mm | Weight Of The Block Making Machine | 6500kgs |

QT10-15 Automatic concrete block machine Main technical parameters:

| Dimension | 7500x2500x3020 Mm | Motor Power | 50.88KW |

| Mould Area | 1220×900mm | Vibration Force | 50KN |

| Working Cycle | 15-18S | Concrete Mixer Model | JS750 |

| Size Of The Pallet | 1220×900×35mm | Weight Of The Block Making Machine | 7000kgs |

FAQ - More About Hollow Block Machine

According to the degree of automatic, it can be divided into automatic hollow brick machine, semi-automatic hollow brick machine and manual hollow brick machine.

According to different forming principles, it is divided into mechanical vibration type and hydraulic forming hollow brick machine.

According to whether it can be moved, it can be divided into egg-laying mobile hollow block machine and stationary hollow block machine.

The mobile hollow block machine is a simple machine with limited capacity, which has the ability to move. It can produce hollow concrete blocks without pallets, but the capacity and shape of the mold is limited. Mobile machines are easier to use and less expensive. But most of the work, such as preparing the concrete, transferring the mortar to the machines and operating the machines, is done manually. This machine has a lower capacity and is suitable for smaller projects with a lower budget.

The fixed hollow block machine is a machine with strong production capacity and high automation. It is usually equipped with some other equipment to form a concrete brick machine production line. It is available in different models, with different degrees of automation, and can be equipped with different optional parts. In general, the number of standard blocks that can be produced by one press of a block machine determines the standard of the hollow block machine.

Material distribution mechanism. Mainly used to is mainly used to send the material in the silo into the forming mold.

Frame. It mainly supports the various parts of the equipment and bears the compression force when the brick is formed.

Silo. Mainly used to store materials.

Pressure head. Used to pressurize the forming of the equipment. It also plays the role of demoulding in the middle of the work.

Plate supply mechanism. It is mainly used for the conveying of pallets. And it is divided into two parts, the front feeding board and the side feeding board, which is also equipped with a scraper and a coating mechanism.

Lifting workbench. Mainly used to drag bricks and vibrate. It is used to form bricks when it rises, and drag out formed bricks when it descends.

Control cabinet. It is mainly used to install the control system of the equipment.

Brick delivery rack. Mainly used to send out the shaped bricks on the workbench.

Hollow bricks machine includes a feeding transmission mechanism, a pressing mechanism, and a finished product output part.

The pressing mechanism is a vertical main body, and two vibrating motors are connected to the vibrating platform at the bottom. The vibration platform is a brick supporting plate, and the middle part of the main body has a lower mold and an upper mold. The lower mold is connected with the upper mold lifting cylinder through the lower mold guide sliding block and the mold lifting screw, so as to use the oil cylinder to lift the mold. The upper die is connected with two pressurized oil cylinders through the guide sliding block of the upper die so as to pressurize the brick body.

The top of the feeding transmission mechanism is a feeding hopper, and the lower part of the feeding hopper is a feeding oil cylinder. The material in the feeding hopper is sent to the brick mold through the feeding oil cylinder. The lower part of the feeding oil cylinder is a pallet conveyor belt, which sends the pallets in the pallet bucket to the vibrating platform.

On the basis of vibration and compactness, the brick body is pressurized by a hydraulic cylinder. The pressure is large and uniform, and the mold is formed, which increases the density of the brick body. Moreover, the transmission mechanism and the output part of the finished product are highly mechanized, which improves the work efficiency.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.