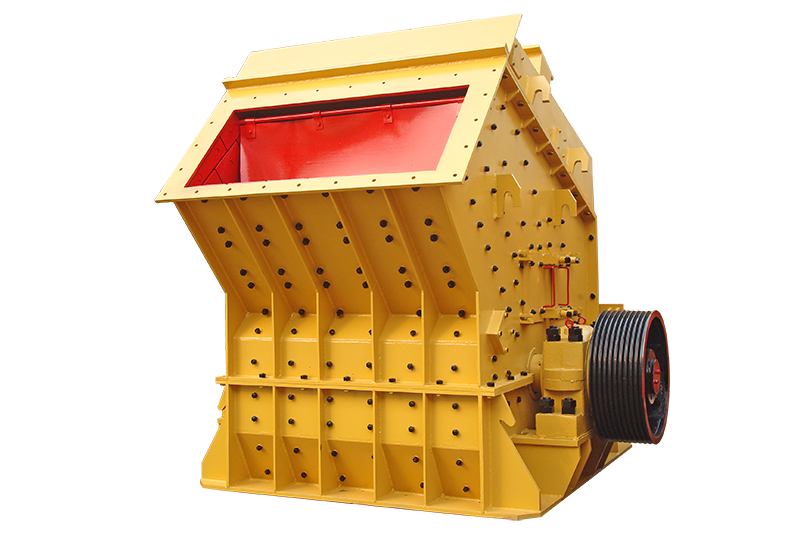

Impact Crusher for Sale

Impact crusher for sale is a kind of high-energy and low-consumption crusher with international advanced level. Its excellent performance makes it play an irreplaceable role in various ore fine crushing equipment. It is the most effective, practical and reliable stone crushing machine.

- From 50-500 tons per hour

- High quality manganese steel

- Three crushing chamber

What Are Main Applications of Impact Crusher Machine

- Widely used in mining, building materials, transportation, metallurgy, water conservancy and other fields.

- This kind of crusher machine also has the function of sand making, so it can also be called sand making machine. This equipment has two functions of crushing and sand making.

- Its outstanding advantages are large production capacity, high work efficiency, energy saving and environmental protection. It is an indispensable equipment in the current sand production line and crushing production line.

- It is usually used as a secondary crusher to crush less hard stones, such as limestone, barite and construction waste, etc.

- Widely used in artificial sand making of metal and non-metal ores, cement, refractory materials, abrasives, glass raw materials, building aggregates, artificial sand, river pebbles, mountain stones, ore tailings, stone chips, building aggregates, and road fabrics , Cushion materials, asphalt concrete and cement concrete aggregate production, as well as fine crushing and coarse grinding of various metallurgical slags.

- It is used together with the hydraulic protection jaw crusher to process various metallurgical slags. It is suitable for construction sand and road construction sand.

Why Choose HAMAC Impact Crusher for Sale

- The structure design is reasonable and novel, the fuselage is stable and the operation is balanced.

- The impact crusher has low energy consumption, high output and large crushing ratio.

- The impact crusher equipment is small in size, easy to operate, easy to install and maintain.

- With the function of shaping, the product is in the shape of a cube and has a high packing density.

- During the production process, the stone can form a protective bottom layer, and the fuselage has no wear and tear, which makes itmore

- The wear parts of the impact crusher are relatively fine, and a small amount of easy-wear parts are made of extra-hard wear-resistant materials, which are small in size and light in weight, and are easy to replace parts.

Technical Parameters of Impact Crusher Machine For Sale in HAMAC

| Model | Rotor size(mm) | Feed opening(mm) | Max. Feeding size(mm) | Capacity(t/h) | Motor Power(kW) | Weight(t) | Overall dimension(mm) |

|---|---|---|---|---|---|---|---|

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 37-45 | 12 | 2330x1660x2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 45-55 | 15 | 2370x1700x2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 17.7 | 2680x2160x2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 100-180 | 132 | 22.4 | 2650x2460x2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 130-250 | 220 | 27 | 3180x2720x2620 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 300-550 | 315-400 | 50.6 | 3959x3564x3330 |

| PF-1620 | Φ1600×2000 | 2000×1600 | 500 | 400-700 | 400-500 | 58 | 4259x3660x3450 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 600-800 | 630-710 | 83.21 | 4400x3866x4009 |

FAQ - More About Impact Crusher Machine

- High energy and low consumption. The stone is impacted, accelerated, bounced, and rubbed in the crusher, so that the ore is broken along the joints and other fragile surfaces until it reaches the set material specification.

- The crushed product is better than natural sand.The impact crusher has a shaping function. The impact crusher has a shaping function. The crushed product is a cube with a low acicular flake content. The particle shape and gradation of sand can be adjusted and improved, so it is widely used in aggregate molding, artificial sand making and high-grade highway aggregate production.

- The particle shape of the crushed products is good. The impact crusher has the characteristics of selective crushing, high crushing efficiency and low energy consumption. Moreover, the particle size of the crushed product is uniform, the shape of the particle is natural, and the material is firm and stable. Therefore, it is usually used in construction and engineering fields that have strict requirements on aggregates.

- Low cost. The impact crusher is reliable, easy to operate, high-efficiency and energy-saving, which not only meets the quality requirements of construction sand, but also makes up for the technical defects of the sand making industry. In addition, various types of equipment can be combined according to different process requirements to meet the different process requirements of customers, and the cost of sand making is low.

The stones fall directly from the upper part of the machine into the high-speed rotating turntable. Under the action of high-speed centrifugal force, another part of the target rock shunted around the turntable collides with the other part of the target stone in an umbrella shape at high speed to perform high-density crushing. After the stones collide with each other, a vortex motion will be formed between the turntable and the shell, resulting in repeated mutual impact, friction, rolling, and then discharged from the lower part. A closed loop is formed multiple times, and the required particle size is controlled by the screening equipment.

The material is crushed by the impact force. Because the crushing force acts instantaneously, the crushing efficiency is high, the crushing ratio is large, and the energy consumption is small. The impact crushing has the following situations:

- The impact of moving objects on the materials.

- High-speed moving materials impact on the fixed working surface.

- High-speed moving materials impact each other.

- The high-speed moving working body impacts the suspended materials.

The hardness of the material. The harder the material is, the more difficult it is to make sand, and the more serious the wear and tear on the impact crusher. The speed of sand making is slow and the capacity is low. Therefore, we need to pay attention to the selection of materials.

The composition of the material. The more fine powder contained in the material before the impact crusher, the more it will affect the sand making, because these fine powders are easy to adhere and affect the transportation. Therefore, materials with a large content of fine powder should be sieved once in advance. Screen the fine powder from the material as much as possible so as not to affect the normal operation of the impact crusher.

The fineness of the material crushed by the impact crusher. The fineness requirement is high, that is to say, the finer the sand-making material is, the smaller the sand-making capacity will be.

The viscosity of the material. The greater the viscosity of the material, the easier it is to adhere. Materials with high viscosity will adhere to the inner wall of the sand making chamber in the impact crusher. If it cannot be cleaned in time, it will affect the working efficiency of the impact crusher, and in severe cases, it may also affect the normal operation of the crusher.

Humidity of the material. When the moisture contained in the material is large, the material is easy to stick in the crusher, and it is also easy to cause blockage during the feeding and conveying process, resulting in reduced sand making capacity.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.