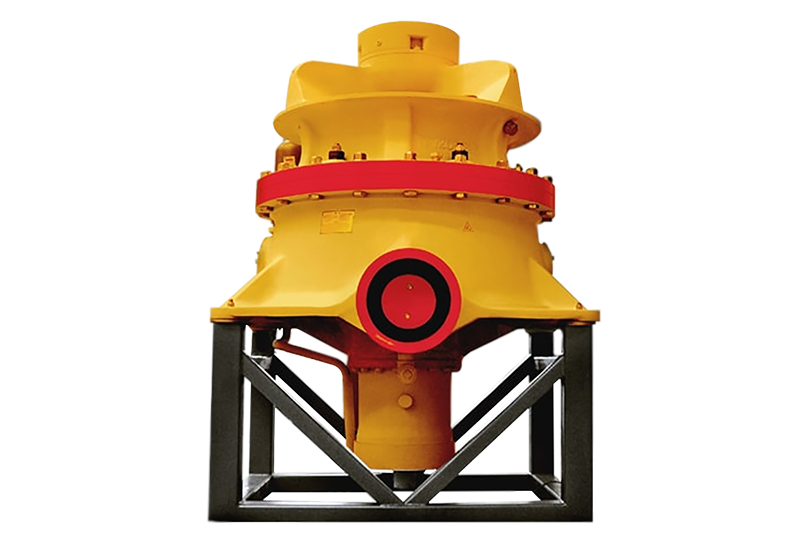

Introduction to Single Cylinder Cone Crusher

Single cylinder cone crusher is a kind of high-efficiency crushing machine developed by adopting the world’s most advanced crushing technology, integrating mechanical, hydraulic, electrical and intelligent control technologies. It can be widely used in metallurgy, construction, highway, chemical industry, building materials industry, suitable for crushing high hardness and high abrasive ores and rocks, especially in the crushing of metal ore and construction sand and gravel materials. Single cylinder crushing machine can be divided into standard type and short head type, which can be applied to medium crushing, fine crushing and ultrafine crushing operations.

Working Principle of Single Cylinder Cone Crusher

When the single-cylinder hydraulic cone crusher is working, the motor drives the pinion of the crusher. The small gear drives the large gear. The large gear assembly drives the eccentric sleeve assembly and the main shaft assembly, centered on the theoretical vertical line, and revolves in the copper bushing. The main shaft assembly can realize self-rotation with the center line of the main shaft in the eccentric copper sleeve.

When the material is fed into the crushing cavity, the main shaft assembly will rotate slowly in the eccentric copper sleeve under the resistance of the material. The running trajectory of the inner cone seems to be swinging back and forth in the crushing chamber while rotating slowly. The material is squeezed and crushed by the swinging inner cone. The connection between the support sleeve and the frame body is compressed by a hydraulic cylinder. When unbreakable objects such as metal blocks fall into the crusher, the moving cone of the single cylinder is lifted by the hydraulic piston at the bottom, which plays the role of adjusting the discharge port, protecting iron from passing through, and repeatedly lifting and falling to eliminate ore blockage.

Technical Parameters of Single Cylinder Cone Crusher for Sale

| Model | Cavities | Maximum feeding size (mm) | Minimum discharging size (mm) | Capacity (t/h) | Maximum install power (kw) |

|---|---|---|---|---|---|

| SCC100 | S1(Extra Coarse) | 240 | 22 | 85-125 | 90 |

| S2(Medium Coarse) | 200 | 19 | 70-95 | ||

| H1(Fine) | 135 | 10 | 46-128 | ||

| H2(Medium Fine) | 65 | 8 | 36-76 | ||

| H3(Extra Fine) | 38 | 4 | 27-57 | ||

| SCC160 | S1(Extra Coarse) | 360 | 25 | 126-215 | 160 |

| S2(Medium Coarse) | 300 | 22 | 108-180 | ||

| S3(Coarse) | 235 | 19 | 91-165 | ||

| H1(Fine) | 185 | 13 | 69-215 | ||

| H2(Medium Fine) | 90 | 10 | 60-160 | ||

| H3(Extra Fine) | 50 | 6 | 45-105 | ||

| SCC250 | S1(Extra Coarse) | 450 | 35 | 267-456 | 250 |

| S2(Medium Coarse) | 400 | 29 | 225-333 | ||

| S3(Coarse) | 300 | 25 | 195-317 | ||

| H1(Fine) | 215 | 16 | 110-380 | ||

| H2(Medium Fine) | 110 | 13 | 115-335 | ||

| H3(Extra Fine) | 70 | 8 | 90-235 | ||

| SCC315 | S1(Extra Coarse) | 560 | 41 | 350-605 | 315 |

| S2(Medium Coarse) | 500 | 38 | 318-630 | ||

| H1(Fine) | 275 | 16 | 177-660 | ||

| H2(Medium Fine) | 135 | 16 | 195-500 | ||

| H3(Extra Fine) | 65 | 13 | 205-320 |

Unique Features of Single Cylinder Cone Crushing Machine

Automatic overload protection system. The crusher is not afraid of excessive iron and material blocking. If the pressure threshold increases, the crushing wall is compressed, pushing the main shaft down. The oil in the hydraulic cylinder at the bottom of the shaft will flow into the accumulator until the gap between the crushed walls is large enough. After the iron is discharged, the pressure of the material on the broken wall is reduced, and the air pressure in the accumulator will return to the hydraulic cylinder. The main shaft resets, the gap between the broken wall and the rolling socket wall returns to normal, and the crusher continues to work normally.

The lubrication system has a clear division of labor. There are two oil inlets for oil filling, one of which enters from the lower end of the main shaft. Lubricated spherical bearings, spherical pads, frame bushings, main shaft bushings, and then lubricate the large and small bevel gears. The other way enters from the transmission shaft end. Lubricate the drive shaft bushing, and the last two lines of oil are discharged from the same oil outlet.

Multi-stage sealing, avoiding the pollution of the oil circuit. It is a long-lasting protection for the main shaft, transmission shaft, gear, good maintenance, and various point bearings.

What Are Advantages of Single Cylinder Cone Crusher

High efficiency. The upper and lower ends of the main shaft of the single-cylinder hydraulic cone crusher are supported, which can withstand greater crushing force and greater stroke. In addition, the special crushing cavity shape adapted to the lamination principle makes the equipment have higher crushing efficiency.

Large production capacity. The single-cylinder hydraulic cone crusher is designed with the perfect combination of crushing stroke, crushing speed and crushing chamber shape. So that the machine has a higher production capacity under the condition of the same diameter of the large end of the moving cone.

Produce high-quality stones. Adopt the unique crushing cavity shape and laminated crushing principle to produce the crushing effect between particles, so that the proportion of cubes in the finished product is significantly increased, the needle-like stones are reduced, and the particle size is more uniform.

Fully intelligent control. The single-cylinder adjustment mechanism makes the adjustment of the equipment very convenient. Even during the operation of the equipment, it can easily realize the arbitrary adjustment of the discharge port. The intelligent automatic control system keeps the crusher in the best working condition all the time, and realizes automatic compensation for wear of inner and outer cone liners.

The hydraulic pressure and lubrication system controlled by double insurance can ensure the machine’s overload protection and good bearing lubrication.

Easily realize various forms of crushing operations. The medium and fine crushing of various cavity shapes can be realized only by changing the fixed cone.

Less consumption of wearing parts and low operating costs. The single-cylinder hydraulic cone crusher has a simple and compact structure, stable performance, and is not easy to break down. Maintenance is convenient and quick.

Advanced plain bearing design. Large carrying capacity and strong adaptability to harsh working conditions. Improve the reliability of equipment operation. The sliding support adopts a special oil wedge design. A stable lubricating oil film is formed on the contact surface between the bearings, which avoids direct friction, reduces heat generation, and prolongs the service life of the bearings.

Safe and reliable insurance system. The high-pressure design meets the low-pressure requirements, and the equipment has a higher pressure margin during normal operation, which improves the reliability of the hydraulic system and ensures timely alarm when the machine is overloaded.

Single Cylinder Cone Crusher Manufacturer - HAMAC

The single-cylinder hydraulic cone crusher produced by our company adopts high-strength cast steel frame, alloy material forged main shaft, high-strength helical gear transmission structure, combined with a variety of cavity types and intelligent operation control system, so that the performance of the equipment and benefits are maximized. It can be widely used in medium and fine crushing operations of various hard minerals and rocks. Meanwhile, its crushing efficiency is high, which can fully meet various crushing needs of customers. Have any need? Feel free to contact us for the best single cylinder cone crusher price now.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.