Stone Crusher For Sale

Stone crusher is an essential piece of equipment in mining machinery, which is designed to break large rocks into smaller rocks, gravel, sand or rock powder. Stone crushers used in mining operations are generally classified according to the degree of raw materials that can be crushed. Check the stone crusher for sale in HAMAC, select the suitable model and inquiry us for quotation now.

The parts of jaw crusher need to be very hard and durable, especially the two working parts of the jaw crusher, the fixed jaw and the movable jaw. Jaw crushers can be further divided into single-toggle jaw crushers and double-toggle jaw crushers.

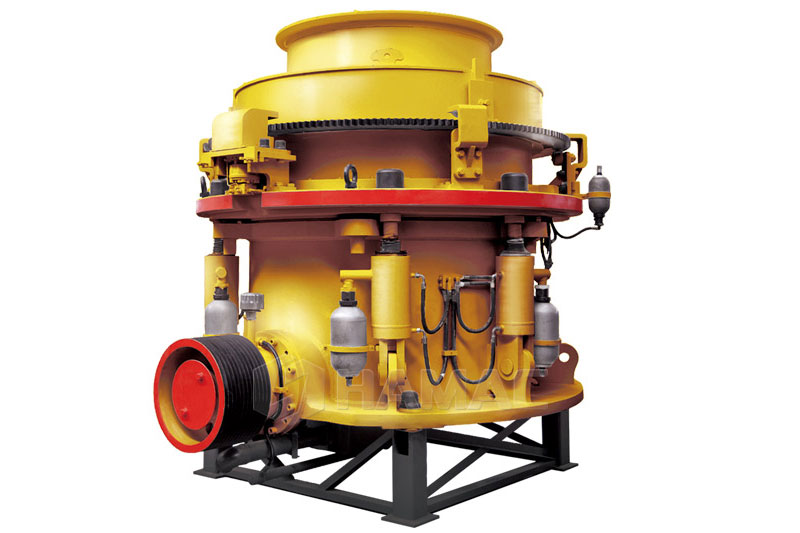

The cone crusher is an advanced hydraulic crusher with high power, large crushing ratio and high productivity. It is generally used as a secondary crusher for crushing medium-hard materials. Meanwhile, it is used as a fine crusher in artificial sand factories and quarries.

Impact crushers are versatile crushers that can be used at any stage of the crushing process. However, the characteristics and capabilities of different impact crusher types vary widely.

Mobile Crusher Plant

Mobile crushing and screening machine can be combined crushing and screening equipment can be divided into fixed type, semi-mobile type and mobile type. This kind of equipment can be widely used in highways, railways, mineral processing, hydropower projects, building materials, municipal garbage and other fields.

FAQ - More About Stone Crusher Machine

Stone crushers can be divided into two categories, crushers that crush materials and impact crushers that use the principle of rapid impact to crush materials. Primary and secondary crushers are used to process coarse material, while tertiary and quaternary crushers break ore particles into finer gradations. Each rock crusher is designed to process a certain maximum size of raw material and typically feeds its output to a sieving machine to sort the product for further processing.

Common stone crushers for sale mainly include jaw crushers, mobile crusher plant, impact crushers, compound crushers, single-stage hammer crushers, vertical crushers, gyratory crushers, cone crushers, roll crusher, double roll crusher, ball mill, etc.

Jaw crushers are heavy equipment for crushing hard rock, mainly used as primary crusher. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyor to the next crushing stage.

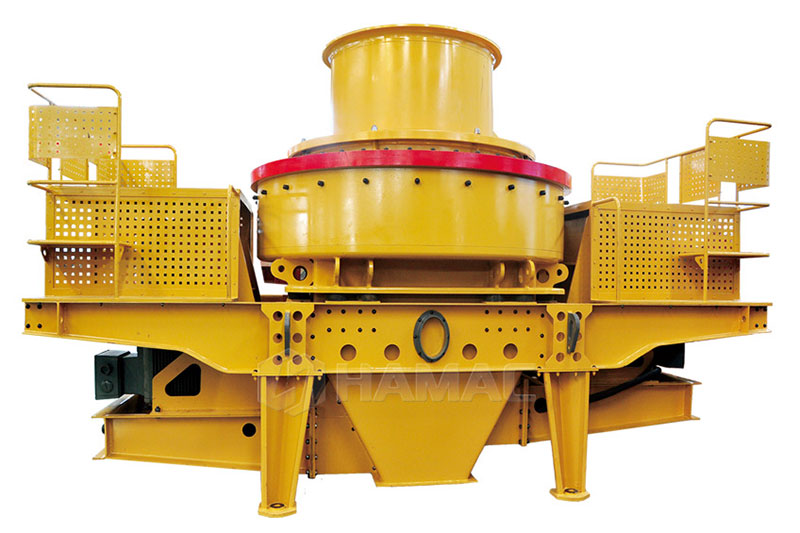

Impact crushers have traditionally been divided into two main types, horizontal shaft impact crushers and vertical shaft impact crushers. These different types of impact crushers share common crushing principles, impact forces, and the ability to break materials down to smaller sizes. But differ widely in functionality, capabilities, and optimal applications.

Cone crushers are popular in secondary, tertiary and quaternary crushing stages. Sometimes, the particle size of the material being processed is inherently small enough that a traditional primary crushing stage is not required. In these cases, the cone crusher can also perform the first stage of the crushing process.

Hammer crusher is a high-speed rotary crushing machine. This kind of stone crusher is suitable for crushing medium-hard materials in cement, chemical, electric power, metallurgy and other industrial sectors. It is also used for the crushing of limestone, slag, coke, coal and other medium hardness materials. Hammer mill rock crusher can not only be used in crushing plants, sand making plants, but also can replace cone crushers in mining plants.

Roller crusher is a very old crushing equipment with simple structure. It can crush iron ore, quartz stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite, potassium albite feldspar, limestone, river pebbles, copper ore, bauxite, barite , basalt, etc. Therefore, the roller crusher is one of the most widely used crushing machines in the mining industry.

Rock roller crusher is a fine crushing equipment similar to hammer crusher. It can crush materials whose compressive strength is less than 160MPA. The feed particle size is moderate, and the discharge particle size is adjustable. It has the characteristics of low maintenance cost, low water requirement, reliable performance, less power consumption, less dust, and low noise.

Various models, strong adaptability. Our stone crusher plant can crush various materials with strong crushing ability.

Good crushing effect and high crushing efficiency. The quality is excellent, and the wearing parts are processed with high-quality materials, which have strong wear resistance and compression resistance.

High degree of automation. Equipped with intelligent devices, our equipment can reduce labor intensity and operating costs.

Reduce consumption and save energy. Compared with the same type of stone crushers for sale on the market, our equipment has higher crushing efficiency and lower energy consumption.

- The stone crusher is suitable for crushing soft, medium-hard and extremely hard materials. Widely used in various ores, cement, refractory materials, bauxite clinker, corundum, glass raw materials, machine-made construction sand, stone materials and various metallurgical slags. Especially for silicon carbide, corundum, sintered bauxite, beautiful sand and other high-hard, extra-hard and wear-resistant materials, the output efficiency is higher than other types of crushers.

- In the field of engineering, it is an ideal production equipment for machine-made sand, cushion material, asphalt concrete and cement concrete aggregate.

- In the field of mining, it is widely used in the front-end process of grinding. It can produce a large amount of fines and reduce the costly grinding load.

- Choose according to the hardness of the stone. Each equipment can adapt to different hardness of materials. Choose equipment with high crushing force and compressive strength or medium crushing force, which is not easy to produce stone powder, and consider its wear resistance and durability.

- Choose according to the output and sizes of stones. Before choosing the model of the equipment, the user should have an understanding of the specifications of the raw materials for production and processing. Different raw materials correspond to different types of stone crusher machines. Choose a matching model for the size of the raw material after processing, as well as the hardness and humidity of the raw material before processing.

- Choose based on output. Due to the size of the processing range of the stone crusher plant is different. Whether it can meet the production requirements per unit time is the key factor affecting the user’s production efficiency.

- Choose according to the actual budget. There are different models of the same device, and these devices will vary in structure and price. Choose a reliable stone crusher manufacturer.

- Select according to the requirements of product quality. The requirements on the finished particle size and stone shape also determine which stone crushing equipment should be selected. Choose HAMAC, our company can not only save the cost of customers, reduce energy consumption, but also create benefits for customers through reasonable matching of other equipment.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.