Stone Crusher For Sale in the Philippines

HAMAC stone crusher for sale in Philippines include various types suitable for crushing different kinds of materials, such as river pebbles, granite, limestone, basalt, ore, rocks, stones, gypsum, coal, etc. In addition, the crushing operation is often divided into coarse crushing, medium crushing and fine crushing according to the size of the feeding and discharging particles. Customers can choose the optimal crusher machine for sale in the Philippines from different dimensions according to different needs.

- Choose from the capacity of the crusher machine. According to the capacity of crusher per hour, it can be divided into large crusher and small crusher.

- Choose according to the crushed material and material size. Different types of stone crusher machine are used in different crushing stages of coarse crushing, medium crushing and fine crushing.

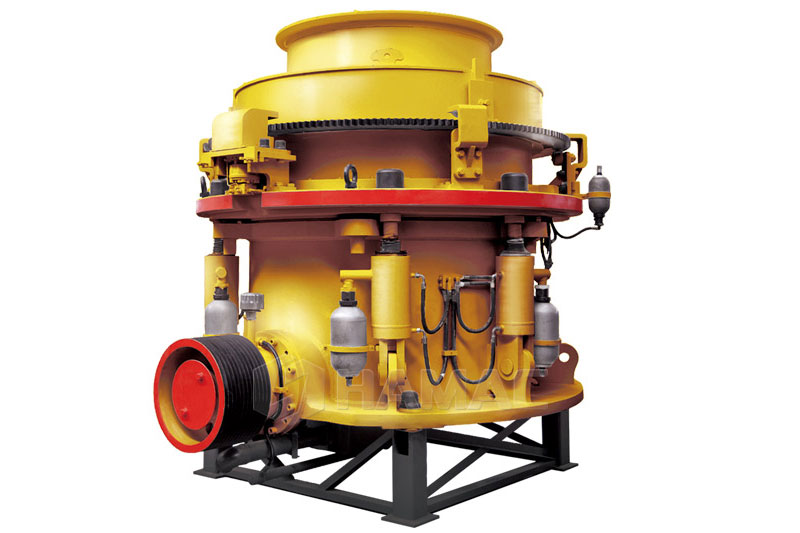

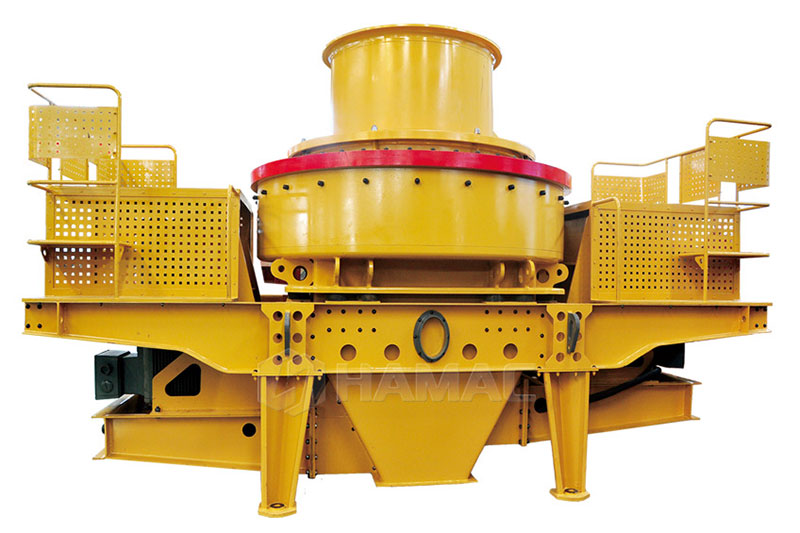

- There are different types of stone crusher machine for sale in Philippines in HAMAC. Jaw Crusher, Cone Crusher, Impact Crusher, Hammer Crusher, Compound Crusher, Roller Crusher are as options. Choose the proper model based on the requirements.

- In addition, we can also provide specially designed stationary and mobile crushing plant in the Philippines. Special designs can be made according to the local terrain and production conditions in the Philippines. Contact our technicians for the design and quotation of the crushing plant for sale in the Philippines.

Stone Crusher Machine Price in Philippines

We have exported many different types of crusher machines to the Philippines. And we have established a dedicated office in the Philippines to provide customers with the best service. Although stone crusher machine price in Philippines varies for different types and models, we can guarantee to always provide our customers with the highest quality and most competitive price crusher machines.

FAQ - More About Stone Crusher for Sale Philippines

When choosing a crusher, it is necessary to fully consider the type, hardness, humidity, specification, particle size of incoming and outgoing materials, output and construction site of the crushed material.

- The hardness of the material. Different types of materials have different hardness, the greater the hardness, the more difficult it is to crush. To crush hard or medium-hard ores, select jaw crushers as primary crushing equipment. For crushing medium-hard or soft ores, select cone or impact crushers.

- The specification of the material. If the size of the material is relatively large, the jaw crusher will be ideal choice. When the size of the stone is relatively small, it is necessary to use other crushing equipment for combination, such as using a jaw crusher anda cone or impact crusher.

- Humidity of the material. When choosing a crusher, pay attention to the moisture content of the material. A large moisture content will lead to an increase in the humidity of the material, thereby increasing the viscosity of the material, reducing the discharge speed of the material, and reducing the production line rate. In severe cases, it may cause blockage of the ore discharge port, cause material blockage of the crusher, and affect the normal operation of the sand making production line.

- The degree of cleavage development of ore. The degree of ore cleavage development will affect the production capacity of the crushermachine. Because the ore is broken along the cleavage plane when it is broken, the production efficiency of the crusher will be higher for the ore with well-developed cleavage.

- The granularity of incoming and outgoing materials. One of the most important factors in choosing the model and grade of crushing equipment is the particle size of the incoming and outgoing materials. If the input particle size is large, but the output particle size is small, it is necessary to use two or more stages of crushing.

- Production requirements. The output requirement of the production line is an important indicator to determine the crushing equipment. If the production output is required to be large, the size and type of crushing machinerequired will be larger, and the capital investment and output of the production line will increase.

- Construction Site. The size of the construction site, such as the production line site, and the specific location of the crushing equipment installation are the most direct factors affecting the selection of crusher equipment.

The life of the hammer head depends not only on the quality of the hammer head, but also on the hardness of the crushed material. Therefore, when selecting the hammer head of the crusher, not only the wear resistance of the material of the hammer head should be considered, but also the performance and characteristics of the crushed material and the impact of the crushing operating conditions on the life of the hammer head of the crusher should be considered.

- The average particle size of the material entering the crusher has a great influence on the service life of the hammer head.

- The output particle size of the crusher.

- The rainy season and wet raw materials.

- The number of times the discharge grate of the crusher is blocked and the length of time it continues to work after the blockage.

- Impurities such as soil and tree roots in the crushed raw materials.

- Whether the working part of the hammer head is worn to a certain extent will have a great impact on the service life of the hammer head.

- According to the design model, properly control the feed size. It is strictly forbidden to put materials exceeding the design maximum size into the machine.

- Select the appropriate feeding equipment, such as apron feeder or vibrating feeder.Ensure uniform and stable feeding, avoid equipment impact and invalid operation caused by uneven feeding.

- Due to the quality error of the hammer head during casting, the hammer head should be turned over in time according to the current situation during use, so that the hammer head wears evenly and the rotor runs in balance.

- When replacing the new hammer head of the crusher, we must weigh it well and divide it into several groups according to the average quality, and the quality requirements of each group are equal.Otherwise, the unbalanced rotor will easily cause vibration when starting.

- Due to the friction during operation, the shaft diameters at both ends of the main shaft are easy to wear. When installing, two bushings should be added to the shaft diameter to protect the shaft diameter.

- After the bearing is worn out, repair and adjust it in time. After the bearing is worn, the bearing bush should be scraped off according to the new size, and the thickness of the gasket should be adjusted to maintain a reasonable gap and form an effective lubricating oil film.

- The materials accumulated in the crusher should be cleaned regularly. The presence of built-up material will severely wear the hammer head and reduce its service life.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.