Twin Shaft Concrete Mixer

Twin-shaft concrete mixer, also known as double shaft concrete mixer, is a horizontal mixer that works through the rotation of two horizontal mixing shafts. It has the advantages of extremely stable performance, strong adaptability, large mixing volume, good mixing effect, continuous production, low noise, simple maintenance and low cost.

- 0.5-4.0m3per batch as options

- Different brands as options

- Customized accessories for it

What Is Twin Shaft Concrete Mixer

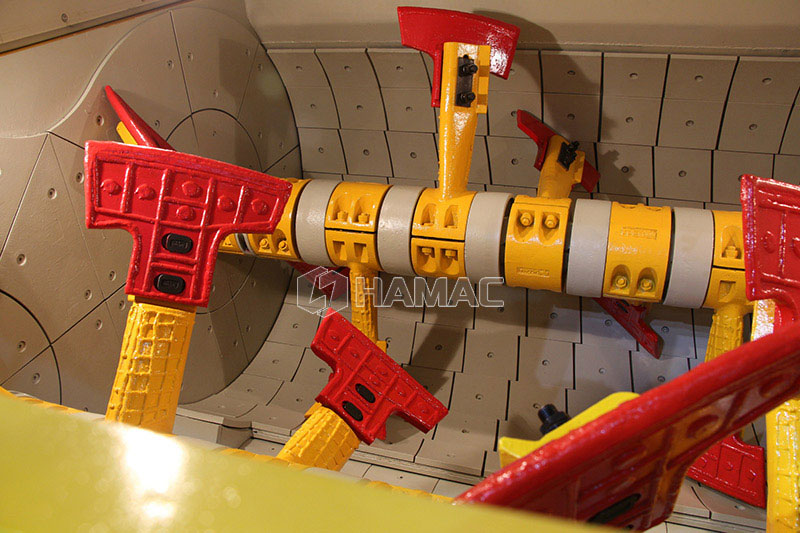

Twin Shaft Concrete Mixer is a kind of high-efficient concrete mixer equipped with two horizontal and parallel mixing shafts on which mixing blades are installed to stir the mixing materials. Typical components of these machines are motors, gearboxes, shafts, tanks and mixing mechanism, blades, arms and linkages. In a twin shaft concrete mixer, each shaft rotates opposite directions, thus preventing collisions between the mixing blades.

What Are Advantages of Double Shaft Concrete Mixer for sale in Hamac?

- Wide range of applications. The design of the mixer can be changed or modified for special applications such as roller compacted concrete, heavy concrete, low slump road concrete, etc.

- Reasonable structure. The equipment has a beautiful design, and its compact structure reduces space occupation, which is conducive to the layout of various working conditions.The double-shaft mixer feeds from the top and discharges from the bottom.

- The mixing speed of the mixer is fast, and the quality is uniform, and the type of material that can be used for mixing is large.

- The spiral blade is made of high wear-resistant special alloy, which is more durable.

- Innovative design concept of twin shaft concrete mixer for sale in HAMAC better solves the problem of the sticky shaft of the mixing powder in the self-falling mixer, improves the mixing efficiency, reduces the mixing load, and increases the product reliability of the mixer.

- Whether it is feeding, unloading, or water supply, the mixer is highly automated.

- All motor control parts are in the electric box, which is safe and reliable in use, and easy to operate and maintain.

- The multi-layer sealing structure combined with floating oil ring, special seal and mechanical seal can effectively prevent the friction of the mixture on the shaft end, effectively prevent the main neck shaft from being rapidly wornand prevent slurry leakage on site.

- The mixing drum made of high-quality steel plate will not deform during use and has a high degree of durability.

Models of Twin Shaft Concrete Mixer For Sale in HAMAC

| Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 | JS3000 | JS3500 | JS4000 | |

|---|---|---|---|---|---|---|---|---|---|

| Discharging Volume (L) | 500L | 750L | 1000L | 1500L | 2000L | 3000L | 3500L | 4000L | |

| Feeding Volume (L) | 800L | 1200L | 1600L | 2400L | 3200L | 4800L | 5600L | 6400L | |

| Capacity | ≥25m³/H | ≥37.5m³/H | ≥50m³/H | ≥75m³/H | ≥100m³/H | ≥150m³/H | ≥180m³/H | ≥200m³/H | |

| Maximum Aggregate Size (Pebble/Gravel)Mm | 40/50 | 40/60 | 60/80 | 80/100 | 80/100 | 80/120 | 80/120 | 80/120 | |

| Cycle Time (S) | 72 | 72 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Total Weight (Kgs) | 4000 | 5500 | 8700 | 11300 | 15000 | 11450 | 12000 | 19000 | |

| Discharge Height (M) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | |

| Mixing Blade | Rotary Speed | 35r/Min | 26r/Min | 29.6r/Min | 24.5r/Min | 24.5r/Min | 21r/Min | 21r/Min | 21r/Min |

| Quantity | 2×7 | 2×8 | 2×8 | 2×8 | 2×10 | 2×10 | 2×11 | 2×12 | |

| Mixing Motor | Model | Y180M-4 | Y200L-4 | Y180M-4 | Y225M-6 | Y250M-6 | Y280M-6 | Y280M-6 | Y315S-6 |

| Power | 18.5kw | 30kw | 2×18.5kw | 2x30kw | 2X37kw | 2X55kw | 2X55kw | 2X55kw | |

| Hoist Motor | Model | YEZ1325-4-B5 | YEZ132M-4-B5 | YEZ160L-4 | YEZ180L-4 | YEJ180L-4 | Y25M -4 | Y25M -4 | Y25M -4 |

| Power | 5.5KW | 7.5KW | 15KW | 18.5KW | 22KW | 2 x55 Kw | 2 x55 Kw | 2 x75 Kw | |

| Pump Motor | Power | 1.1KW | 1.1KW | 3KW | 3KW | 4KW | 5KW | 5KW | 6KW |

FAQ - More About Twin Shaft Concrete Mixer

The mixing process of the twin-shaft mixer occurs not only in the radial direction, but also in the axial direction. The main mixing zone is located in the circumferential direction of the stirring body. During the entire mixing process., the energy value along this direction reaches the maximum. Therefore, the mixing space can be fully utilized, so that the aggregate, cement and water can achieve the most uniform and optimal mixing mode in the shortest time under the condition of low peripheral speed of the mixing blade, and achieve the best mixing effect.

The machine consists of a frame, a mixing drum, a transmission system, a mixing system, an unloading device and a control system. The mixing drum and the mixing frame are made of twin-shaft mixer equipment, and are welded by medium-thick steel plates and channel steel. The stirring shaft, the stirring arm and the stirring blade form the stirring device. The blades are arranged on the stirring arm, and the stirring arm and the stirring shaft are designed to be integrated to form a back to the spiral direction. The gap of the stirring device can be adjusted according to the properties of the stirring material.The transmission device of the double-shaft concrete mixer is composed of a reducer and a coupling. The unloading device is composed of an oil reduction motor, a sprocket and a chain.

- The stirring device presents an intermittent helix, and the stirring operation is formed in an axial and radial form to form a three-dimensional running track.This form can make the stirring work more rapid and reduce energy consumption.

- The concrete mixing drum has a large volume ratio, high material mixing efficiency, and effectively avoids the problem of shaft holding during use.

- The double-shaft wet mixer is driven by a cycloidal pinwheel reducer, with stable rotation and low noise.

- The twin-shaft mixer adopts a fully automatic lubrication system, and oil is supplied by an independent oil pump, with precise dosage and reliable performance.

- It is equipped with a humidification water spray system to ensure uniform water spray and adjust the water supply to meet the needs.

- Unique paddle structure. The paddle structure of the twin-shaft mixer is specially designed for strength and wear resistance.

- The bearings are placed in a specially designed housing on the outside of the mixer, preventing the ingress of cement grout.

The working principle of the twin-shaft forced mixer is simply that the transmission mechanism rotates the mixing shaft in the cylinder through the coupling. The rotary motion of the mixing blades shifts the center of gravity of the mixture accordingly, and this cycle makes the mixture obtain a more ideal mixing effect. The movement characteristic is that the mixing mechanism and the mixing material make a relatively large relative movement, and the material makes short-distance movement in both radial and horizontal directions.

The mixing drum of the twin-shaft mixer is two connected grooves. It is equipped with two horizontally arranged stirring shafts. When the stirring shaft rotates, the mixture at the bottom and the middle of the mixing tank is turned upwards. And on the other hand, the mixture is pushed back and forth along the axis so that the mixture is stirred quickly and evenly.

When materials(cement, aggregate, water, additives, etc.) flow into the mixing drum, the double-shaft concrete mixer starts the mixing process. The mixer creates a spiral motion to make the concrete more uniform. The mixing process continues according to the mixing time required by the recipe. Using scrapers located at the start and end of the shaft, all the concrete is collected and ready for the discharge process.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.