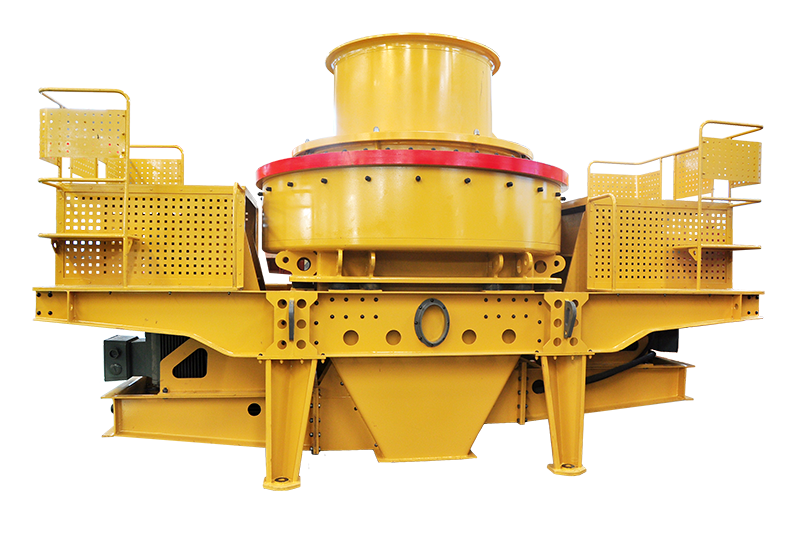

Vertical Shaft Impact Crusher

The vertical shaft impact crusher has the characteristics of stable and reliable operation, convenient maintenance and high sand making rate. It is especially suitable for stone shaping and machine-made sand production, and can be widely used in fine crushing operations in industries such as hydropower, highways, construction, cement, and metal mines.

- From 30-200 tons per hour

- Durable and long life hammer

- Deep crushing chamber

What Are the Main Components of Vertical Shaft Impactor

The structure of the vertical shaft crusher is composed of body, main shaft, rotor, liner, inlet and outlet. The material enters the first crushing cavity and is crushed by the impact of the plate hammer on the rotor with high speed rotation. The material blocks that have gained kinetic energy are thrown to the liner of the cylinder for further crushing. The block groups collide with each other in the machine cavity and get broken for the first time. When the material enters the second crushing chamber, it is squeezed and impacted by the second rotor, and the material layer is compacted and becomes dense. With the extrusion, the impact force increases. When the stress exceeds the strength of the particles, the material is crushed.

Excellent Working Principle of Vertical Shaft Impact Crusher

The main advantage of vertical shaft impact crushers over other stone crushers machine is due to its unique design features. The vertical shaft impact crusher mainly uses a belt to drive the central vertical shaft to rotate the flat parts equipped with vertical guides. The rotor ejects the material horizontally to the impact plane in the crushing cavity through the centrifugal force at a very high speed.

Equipped with solid casing base, two flange-mounted vertical motors symmetrically aat both ends. The high-speed rotating rotor is jointly driven by the multi-groove belt pulley, and the stone is thrown from the tangential direction of the throwing port to hit the anvil ring, so as to realize the crushing of the stone.

Technical Parameters of Vertical Shaft Impact Crusher For Sale in HAMAC

| Model | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 |

|---|---|---|---|---|

| Center and Ring feeding | 150~280 | 240~380 | 350~540 | 500~640 |

| Center feeding | 70~140 | 120~200 | 180~280 | 250~360 |

| Soft material | < 35 | < 40 | < 45 | < 50 |

| Hard material | < 30 | < 35 | < 40 | < 45 |

| Rotation speed (r/min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 |

| Power of double motor (KW) | 110~150 | 180~220 | 260~320 | 400~440 |

| Overall dimension L x W x H (mm) | 4100× 2330× 2300 | 4140× 2500× 2700 | 4560× 2600× 2900 | 5000× 2790× 3320 |

| Weight (t) | 8.6 | 11.8 | 17.5 | 27.5 |

| Power for oil pump | 2 x 0.31 KW | |||

| Safety | To make sure the supply of oil with double oil pump, working without oil, temperature when water cools, start the motor by heating it in winter. | |||

| Power for oil box heater | 2 KW | |||

| Overall dimension L x W x H (mm) | 820 x 520 x 1270 | |||

Content Index

FAQ - More About Vertical Shaft Impact Crusher Machine

The main frame is sequentially equipped with a feeding cylinder, a distribution frame, a crushing chamber, a rotor, a motor and a discharge box. A feeding inner cylinder is arranged inside the feeding cylinder, and a crushing chamber cover plate is arranged between the feeding cylinder and the crushing chamber. The motor is located in the center of the discharge box, and the output shaft of the motor is coaxially arranged and connected with the rotor. The rotor is located in the crushing cavity, and the wear-resistant lining plate is installed on it. Shock absorbing springs are arranged on the frame between the crushing chamber and the discharge box. An air dust removal device is provided on the side wall of the feeding cylinder. The crusher is driven by a single motor, which can save energy consumption. The motor and the vertical shaft are set coaxially, and the force on the vertical shaft is uniform during operation, which prolongs the service life of the vertical shaft and related components. In addition, there is an air dust removal device on the side wall of the feeding cylinder, which eliminates dust pollution and is environmentally friendly.

The main shaft is the main part of the crusher supporting the rotor, and the impact force is borne by it. Therefore, the material of the main shaft is required to have high hardness and toughness. When the crusher is reversed, the hammer frame is in contact with the material, which is easy to cause wear, so the selected material must have certain wear resistance.

The wear resistance of the hammer head is one of its main quality indicators. Improving the wear resistance of the hammer head can shorten the maintenance and parking time of the crusher, which can greatly improve the utilization rate of the vertical shaft impactor and reduce the maintenance cost.

The cover part is composed of a cover, a rolling bearing, a tapered sleeve, an upper bearing cover, an upper sealing ring, a round nut and a straight-through oil cup. The bearing cover is used for the outer circle positioning of the bearing. The inner linoleum groove in the bearing cover is used to install the linoleum to play the role of sealing oil. There is a raised ring outside the bearing cover to block the dust outside from entering the bearing cover. The bearings are lubricated with straight-through oil cup oil, and can realize the adjustment of the bearing clearance by adjusting the gasket.

The base part is composed of supporting sleeve, rolling bearing, lower bearing cover, lower sealing ring, shaft sleeve, gasket, oiling device and base. The base is used for the positioning of the entire rotor shaft. The support sleeve is used to support the two rolling bearings and the lower bearing cover. Spherical roller bearings are mainly used to bear axial force. Thrust spherical roller bearings mainly bear radial force. Add a spacer between the two bearings to separate the two bearings to avoid direct contact between the two bearings, which will affect the life of the two bearings. The annular seal formed by the lower bearing cover and the lower sealing ring is used to block the dust in the cylinder from entering the bearing.

- Before starting the machine, check whether the observation door of the vortex chamber is closed tightly to prevent materials from rushing out of the observation door of the vortex chamber, which may cause danger.

- Check the direction of impeller rotation. Looking from the direction of the inlet, the impeller should turn counterclockwise. Otherwise the motor wiring should be adjusted.

- The starting sequence of the crusher and conveying equipment is discharge, crusher, and feeding.The crusher must be started without load, and the material can only be fed after the crusher is running normally. The shutdown sequence is the reverse of the startup sequence.

- The feed particles are strictly in accordance with the relevant regulations, and the materials larger than the regulations are prohibited from entering the crusher.Otherwise, it will cause the imbalance of the impeller and excessive wear of the impeller, and even block the impeller passage and the central feeding pipe, so that the crusher can’t work normally. If it is found that there are too large pieces of feed, it should be eliminated in time.

- When the discharge equipment stops, the feeding should be stopped in time. Otherwise, the impeller will be crushed and the motor will be burned.

- Feeding strives to be continuous and uniform.

- During the operation of the crusher, there must be no severe vibration and abnormal noise. Otherwise, stop and check.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.