Hollow Block Machine For Sale in the Philippines

HAMAC hollow block machine in Philippines can be used to produce various types of bricks, including hollow cement blocks, blind holes, standard bricks, etc. Meanwhile, it is very convenient to use, only need to change the mold, can realize the production of different types of bricks. The hollow block maker for sale in Philippines has a wide range of material application capabilities. It is not only suitable for the production of concrete hollow blocks, but also suitable for processing industrial waste (such as sand, stone, fly ash, slag, tailings slag, coal gangue, perlite, and ceramsite) into various new wall materials. There are manual type, semi-automatic type and automatic hollow block machine for sale in Philippines for customers to select based on their requirements. Contact us now the hollow block machine price list in Philippines now, we will reply in 24 hours.

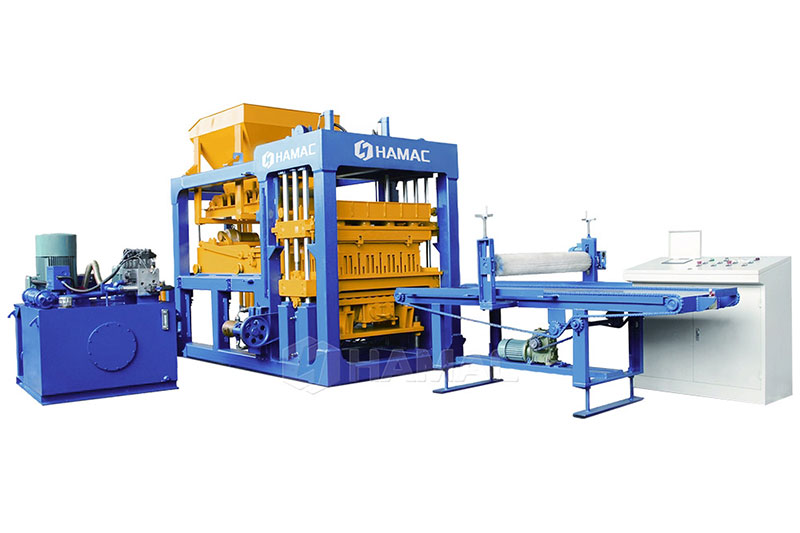

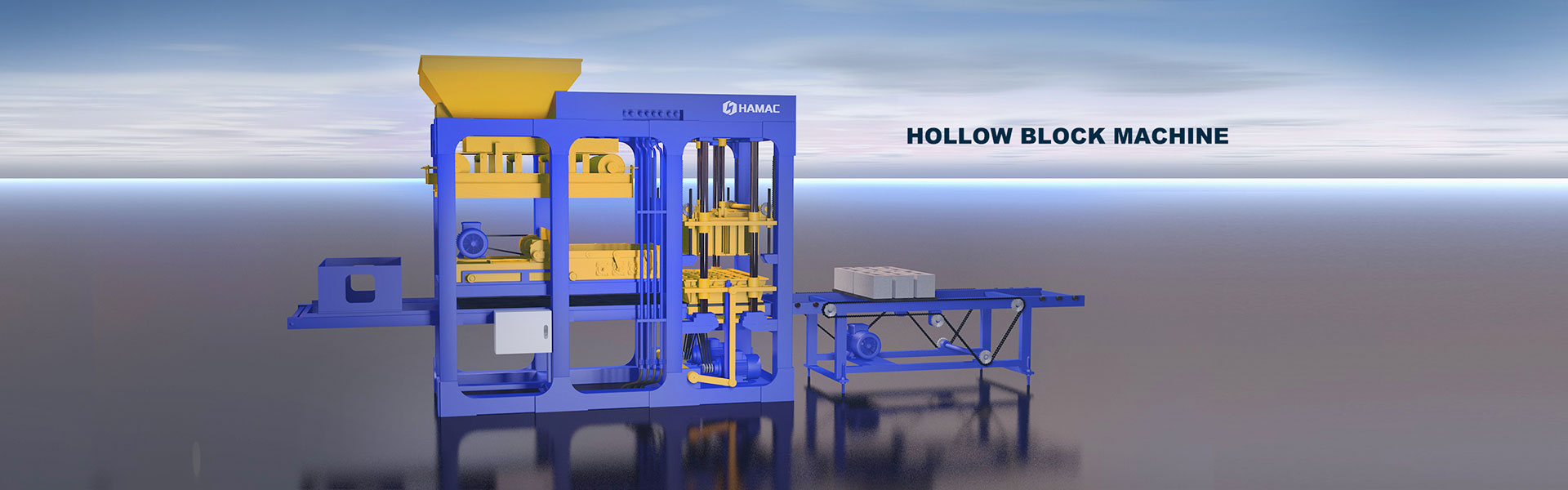

Automatic Hollow Block Machine Philippines

The automatic hollow block machine Philippines is a kind of brick making machine which is controlled by a computer, automated, easy to operate, and highly productive. The pressure of the equipment is relatively high, so it can achieve fast brick production efficiency. As a relatively high-tech equipment, it can automate a series of brick-making processes.

Semi-automatic Hollow Block Making Machine in Philippines

The excellent feature of semi-automatic hollow making machine in Philippines is low energy consumption, large output and cost saving. The model sold by our company has advanced design and wide applicability.

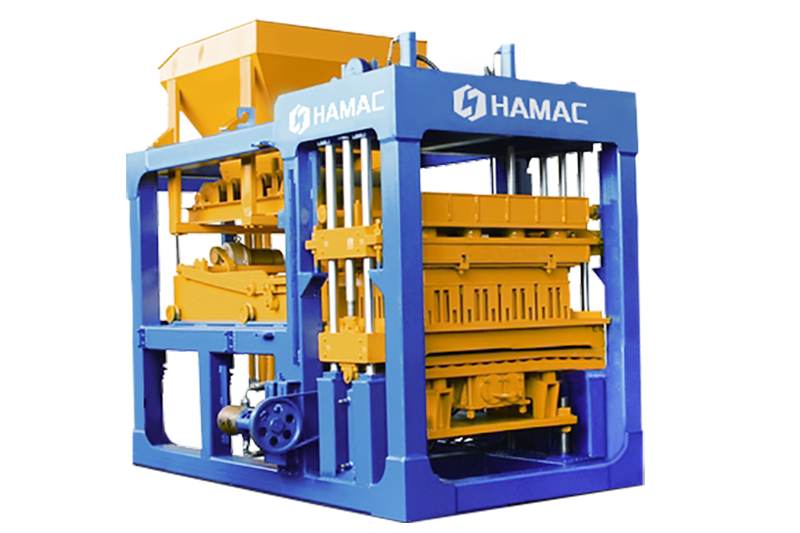

Hydraulic Hollow Block Machine Philippines

The hydraulic hollow block machine Philippines has a high degree of automation and better product performance. It can withstand more pressure and exhaust times during the pressing process. In addition, the equipment has high production efficiency and high safety.

Manual Hollow Block Maker for Sale Philippines

The equipment is relatively cheap and suitable for small investment and development. But it can still produce various types of bricks, including basic wall standard bricks, and different bricks can be produced by changing different molds.

Hollow Block Machine in Philippines Successful Cases

FAQ - More About Hollow Block Machine in the Philippines

Hydraulic system. Adopting advanced hydraulic dual-proportional control technology, the pressure and oil volume of any branch of the hydraulic system can be easily regulated, so that different raw materials can be used to produce the same high-quality products.

Electric control system. The whole process is intelligently controlled by PLC, equipped with data input and output devices to realize ideal man-machine dialogue. The control system also includes advanced safety logic control and fault diagnosis system. Optional remote control.

Feeding system. The unique forced material distribution mechanism and the special arch rod adapted to the change of different mold cavities have the effect of forced arch breaking and secondary stirring, which can ensure the uniformity of large-volume fly ash distribution to the greatest extent.

Vibration system. Special technology is adopted to optimize the layout of the vibration axis, so that the vibration is evenly distributed in the entire range of the platen, thereby greatly improving the consistency and stability of the product performance, and making higher quality products under the condition of the same ratio. At the same time, noise can be effectively reduced. The unique design of the fixed table can improve the speed of product forming and the accuracy of product size.

The mold is precision casted at one time, and through carburizing treatment, each set of molds can be replaced separately during use. This kind of mold can be refurbished, which greatly reduces the cost of mold use.

The cantilever-type rigid synchronous mechanism ensures that the molded bricks will not be damaged during demoulding.

Three points that need special attention when choosing an Hollow Blocker Maker in Philippines.

- The quality of equipment is the first factor for customers to choose products.

- The strict quality control of the brick making machine is based on a strong technical foundation.

- After-sales service. An excellent hollow block maker manufacturer should have excellent after-sales service force and good parts supply. It is very important to invest in machinery to set up a factory, and the follow-up supply of parts.

Therefore, when choosing a hollow brick machine in Philippines, you need to pay attention to the following points:

First of all, it is necessary to choose an equipment manufacturer with excellent quality and reputation.

Secondly, before purchasing, go to the factory to inspect the materials and parts used by the equipment manufacturer in the production process to ensure that the source of these materials guarantees the quality.

Thirdly, try to choose a model with a large number of moldings at one time, because the number of moldings at one time of the brick machine will directly affect the output of the brick factory.

Based on all these characteristics, HAMAC hollow block machine for sale in Philippines will be your ideal choice.

The ex-factory machines have been tested in the factory according to the relevant regulations, but due to long-distance transportation and long-term placement, the following inspections should be carried out when installing hollow block maker machine.

- Check whether the brick machine is damaged or deformed during transportation (especially pay attention to the hydraulic pipeline).

- Check whether the fasteners in the main parts of the brick making machine are loose.

- Check the reducer. Whether the oil cylinder and each lubricating point of the vibrating table are refueled as required, and whether the oil quantity is appropriate.

- In addition, it is necessary to carry out a comprehensive wiping work. Before the test machine, lubricate the relatively sliding parts of each moving part according to the regulations.

- If the machine needs to be disassembled due to transportation, it can be divided into forming device, plate feeding device, material feeding device, brick discharging device, palletizing device, phase electric control device, etc. When installing, it should be assembled in place according to the assembly relationship.

- The power system is the core power of the entire device. The stability and safety guarantee of the power system is also the prerequisite for the stability and safety of the entire production workshop.

- The motor of the oil pump is stopped or rotated hard, causing the motor to burn out. The reason is that the main pressure regulating valve of the equipment (the big nut under the distributor) has too much pressure regulation.

- The vibrating force of the vibrator is insufficient, the brick output cycle is long or the brick output is loose, the reason is that the pressure of the lower die is adjusted too much.

- If the pressure regulating valve fails, the reason is that the pressure spring in the pressure regulating valve is damaged or invalid. The pressure spring of the same type should be replaced in time.

- If oil leakage is found in the oil cylinder, the reason is that the seal in the cylinder loses its sealing effect. The corresponding type of seal should be replaced.

- Pay more attention to maintenance and maintenance when using equipment, so as to reduce equipment damage.

Our company has a dedicated technical team. In case of any problems, please feel free to contact our technical team for help.

Contact Us

Please fill in the below information. Your information will be kept strictly confidential and will not be used for any purpose other than our business

TEL: 0086-15136236223

EMAIL: [email protected]

SKYPE: hamacchina

ADD: 57th, Kexue Avenue, National HI-TECHIndustrial Development Zone, Zhengzhou,China.